Food is one of the things that make life good, and in so many ways. The concept of 3D printed food could make us even more excited: a great innovation in itself, it allows for amazing customization, sustainability by reducing food waste, intricate designs, and even the potential to address food scarcity and malnutrition. What’s not to love?

In this article we’ll take a look at how 3D printing food works, explore the exciting recent 3D printed food projects, and suggest which 3D printable foods you can currently try!

The process

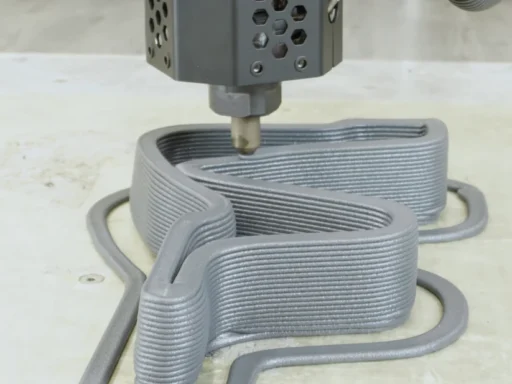

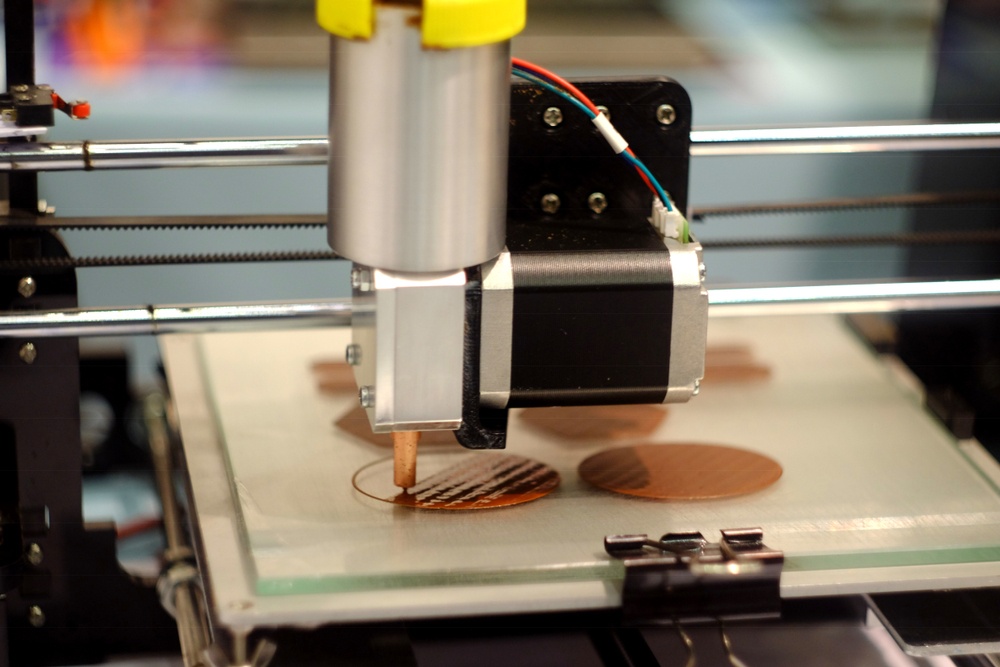

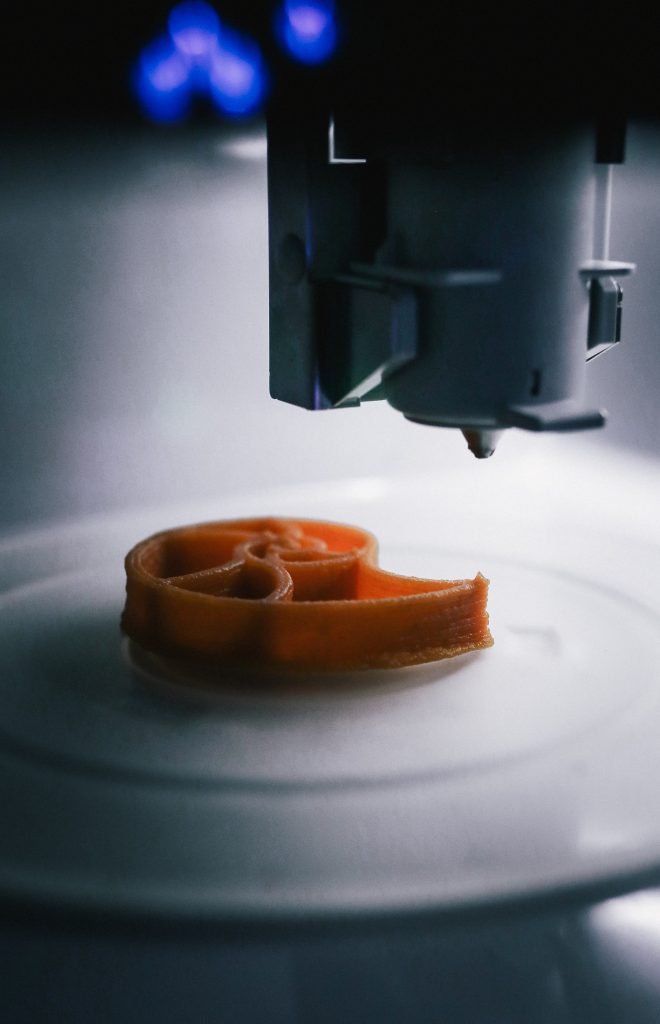

Typically, 3D printing food involves using a special 3D food printer (based on FDM-like technology) to pump out edible “ink” – materials like puree, paste, or dough. While a traditional filament for FDM printers is plastic, food 3D printers may use tomato sauce or chocolate. These safe 3D printing filaments, layer by layer, form a desired food item: this is possible with the printer’s program or digital design, when the edible material is deposited in particular shapes and patterns. Hope you’re not too hungry while printing – though who could blame you for getting excited at the thought of a heart-shaped pizza, or a gift of some personalized candy!

Now, we can’t say 3D printed food is easily available or affordable yet, but looking back at its history we can expect the technology to grow in the future as it rapidly develops even as its costs decrease. The concept is not as new as back in the early 2000s when NASA was thinking of the idea for future space missions. In 2006, the first 3D printer capable of printing chocolate was introduced at Cornell University, as part of the “Fab@Home” system. A diverse range of enthusiasts, researchers, chefs, and 3D prodigy experimented with the technology since, and today’s food printers have earned their rightful place on the market and in kitchens – and in space too, of course.

The projects

The 3D printed food projects are dynamic and constantly evolving, with tens of new ideas quickly emerging, from pastries to drinks to burgers. Let’s take a look at some of the amazing initiatives that impressed both the 3D printing community and the general public.

1. Oshi (Plantish). The revolutionary project started by a crew of foodie-scientists dedicated to developing plant-based alternatives to fish, meat, and more animal products. Primarily, Oshi is aimed at recreating the exact taste and texture of fish and making these cruelty-free options not only sustainable, but delicious (no fishy business!). The project employs advanced 3D technology to make environmentally friendly fish and meat stakes for a healthier planet.

2. “Print a Drink” by MIT’s Tangible Media Group. This project is a combo of 3D printing technology and mixology. Ever wondered if you could design and print customized edible substances to put in your glass? In fact, it is possible to precisely control the liquid’s flow and composition. The project definitely pushed the boundaries of beverage design to offer one-of-a-kind sensory experiences.

3. Barilla’s 3D Printed Pasta. The world-famous Italian company developed its own 3D printer for making fresh pasta in collaboration with TNO back in 2016. The exciting project brought together traditional Italian pasta-making art and next-gen 3D technology. The result? New possibilities for pasta design of all sorts of customizable intricate pasta designs with unique texture and shape – at least 15 different kinds!

4. Food Inc. The first ever 3D-printing restaurant, the project invites diners to “taste tomorrow today”, offering every type of food, kitchen utensils, and even all the furniture made with the help of 3D printing technology to guarantee an immersion into a futuristic experience. A great adventure for a true gourmet, Food Inc is a truly conceptual place that demonstrates how cutting-edge technology can be gracefully combined with art and philosophy.

The foods

Now, with all of these fascinating projects, the question still remains: what are the exact kinds of food that can currently be 3D printed? With pastes, powder, gels, or liquids being arguably the easiest “ink” for the 3D printing process, you could think of desserts, but modern food 3D printing has evolved to work with fantastically diverse (and complex!) materials and shapes.

Here are just a few examples:

Pizza

BeeHex is one company specializing in 3D printed pizza, as well as automating and streamlining the pizza production processes. Bearing in mind dietary restrictions and individual preferences, the team developed a specialized 3D printer and a bot called the Chef 3D that could extrude pizza ingredients in precise layers. BeeHex’s software, in turn, was responsible for customizing the size, shape, and toppings of pizza, and even arranging the ingredients and calculating nutritional information.

Cheesecake

A group of engineers from Columbia University conducted a study that involved using a 3D printer and laser technology to create a vegan cheesecake with seven ingredients. According to the NPJ Science of Food journal, the researchers saw great potential in the possible applications of 3D printing for mechanically assembled food. While the machines for creating and baking 3D-printed desserts exist in Columbia Engineering’s laboratory, the scientists hope for more practical implementation of this technology in cooking.

Chocolate

The world’s first commercial chocolate 3D printer is called Choc Creator, and it can make mind-blowing chocolate designs. This innovation led to the establishment of a company called Choc Edge, which eventually became the first commercial manufacturer of 3D printers specifically designed for chocolate printing. As in a typical 3D printing process, chocolate is melted and carefully extruded layer by layer to form various sweet structures, allowing for the production of more personalized chocolate creations. Chocolate lovers rejoice!

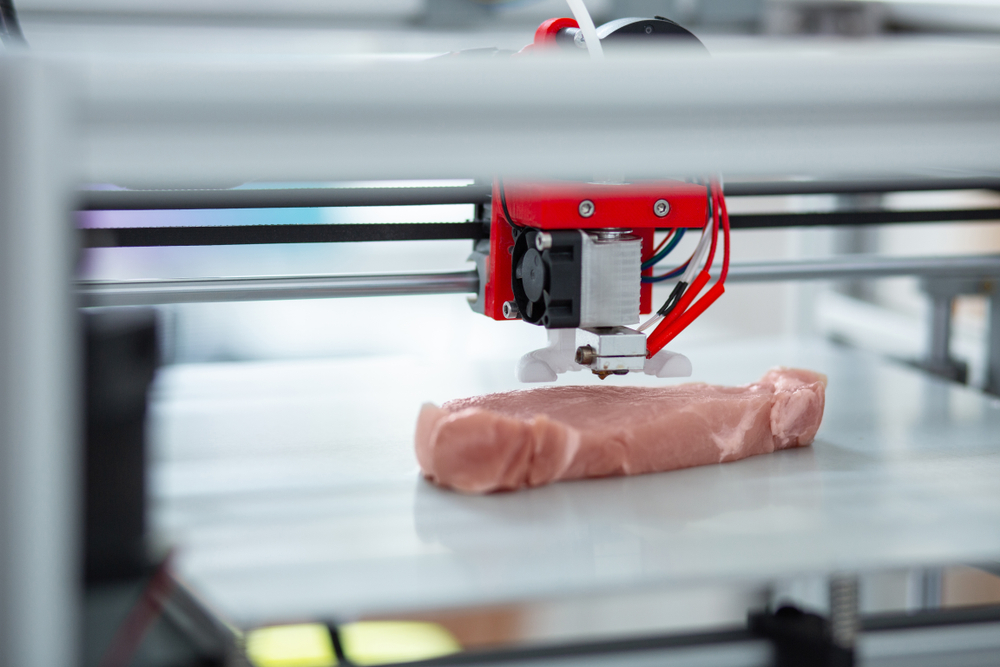

Raw meat

Finally, even those who are always up for a good steak can benefit from 3D printing. Stakeholder Foods is one of the numerous companies that innovated meat production with the help of 3D technology. Here’s the gist of what you need to do to 3D print your steak the way the project does: use a bio “ink” derived from stem cell lines. This ink then needs to be loaded into a specialized printer for bioprinting a meat cut based on a digital design. The printed meat is then transferred to an incubator, where the cells undergo a differentiation process for several weeks, transforming into muscle and fat cells. Easy, right? Or, just see what they’re up to and how you can sink your teeth in here.

The potential

3D printing food is obviously a great innovation, even with such limitations as the number of ingredients and the relatively expensive workflow. With the technology developing, the advantages will eventually outweigh the concerns, offering precise customization, sustainability by reducing food waste, the production of complex and intricate designs, efficiency in food preparation, and – most importantly – providing easily digestible and nutritionally optimized meals, especially for those with specific dietary requirements or limited access to traditional food sources.