PLA, or polylactic acid, is the material of choice for many makers and professionals when it comes to fused deposition modeling (FDM) 3D printing. This is because it is simple to use, inexpensive, and easily accessible. In addition to that, with the variety of PLA available today, you can print some remarkable aesthetic pieces as well as functional parts.

In this article, we’ll learn about the 3D printing material PLA. Along with the benefits and drawbacks of printing with PLA, it is important to understand the best tips and slicer settings to ensure a successful print. So, without further ado, let’s look at how to get the most out of your PLA 3D printing experience!

Read our overview about all common 3D printing materials here.

What is PLA material?

PLA is an eco-friendly plastic primarily made from naturally obtainable starch, available in plants like corn or sugarcane. With the help of a mechanical process, this starch undergoes a chemical reaction. The result of this transformation is a manufacturing polymer.

PLA is both biodegradable and recyclable because it is made from natural raw materials, making it an excellent plastic for prototyping with. In addition, PLA is a versatile material for several reasons. It is simple to use, available in a variety of colors and finishes, suitable for numerous applications, and relatively affordable.

Benefits of printing with PLA

PLA is a popular and widely used 3D printing material because it offers numerous advantages. Whether you are a beginner or an expert, there is no denying that printing with various types of PLA is effortless and fun. So let’s take a closer look at some of the most significant benefits of printing with PLA.

The filament is relatively easy to use for 3D printing as it is compatible with most entry-level FDM 3D printers. You can often begin printing with PLA using the generic slicer settings and recommendations for your particular printer.

Many users prefer printing with PLA because it is inexpensive and widely available. As a result, numerous guides and solutions are also available to help you troubleshoot any issues you may encounter.

As a 3D printing material, it is quite forgiving, which means the chances of failure are low. Even as a beginner, you can play around with its print settings and still get exceptional results.

You can attribute PLA’s affordability to several factors, the most important of which are abundant raw materials and a simple manufacturing process. Thus, PLA is less expensive than other filaments such as ABS and PETG.

As a result of the factors above, PLA has also become easily accessible. There are tons of different manufacturers and sellers that provide a wide array of PLA. These are available in a spectrum of colors and varying types, such as wood PLA and transparent PLA.

Another of the notable benefits of PLA is its biodegradability. PLA can break down into its basic elements under certain environmental conditions, such as the right temperature, level of humidity, and the presence of microorganisms.

This process can take anywhere from a few months to several years. Under less favorable conditions, however, the process could take longer.

Drawbacks of PLA

While 3D printing with PLA has many advantages, it also has some significant drawbacks. Here you will notice that some of its shortcomings are inherent, while others are where PLA falls short compared to other 3D printing materials.

PLA is a hygroscopic material – meaning that if left out in the open without proper care, it tends to absorb moisture due to the humidity in its surrounding environment. This moisture the PLA has entrapped can lead to poor quality 3D printed parts. This is because it can cause blobs due to irregular extrusion, affecting your surface finish and final print quality.

It is inadvisable to use PLA for parts that will get sunlight’s constant exposure or that will be in close proximity to heat. Due to its low glass transition temperature, you must be cautious when using PLA in high-temperature conditions. This characteristic can cause printed parts to deform even at temperatures as low as 50 to 60°C (122 to 140°F).

Another drawback of PLA, is that it’s difficult to post-process compared to materials like ABS.

ABS has a well-established method for achieving a finished look called vapor smoothing, which involves exposing the printed part to acetone vapors. However, there is no equivalent vapor smoothing method for PLA.

PLA post-processing options are more limited, often requiring manual techniques such as sanding, filing, or the use of filler materials to achieve a smoother surface. Despite investing considerable effort and time in manually post-processing PLA, the results may not be as consistent as vapor smoothing with ABS.

Tips for 3D printing with PLA filament

Even though PLA is easy to use, fine-tuning some basic print settings is essential. This ensures consistent, quality 3D printed parts when using PLA filament. This section will cover some of the most important settings and printing tips for successful 3D prints.

Print temperature

A heated bed is not always necessary for PLA, but it can improve first-layer adhesion and minimize warping. The recommended bed temperatures for it range anywhere between 40-60°C (104 to 140°F).

On the other hand, the optimal extruder temperature for PLA varies depending on the specific filament and printer, and typically ranges between 180-220 °C (356-428° F).

It’s crucial to find the right temperature for your specific PLA filament. Going too low or too high can cause some kind of print failure. To find the appropriate temperature for your filament and ensure that you’re getting the best possible results, you can print a temperature tower.

Print surface

PLA adheres well to most print bed surfaces, including glass, PEI, and BuildTak. You can get excellent first-layer adhesion just by printing on a glass print bed. However, if you want to improve adhesion, use blue painter’s tape or a layer of glue stick on the print bed.

Alternatively, you can use any flexible print bed, such as a PEI sheet build plate, if you want high convenience and improved adhesion. The printed part easily comes off by flexing the plate slightly.

Speed settings

Print speed can significantly impact the quality of your PLA prints. Slower print speeds generally result in better layer adhesion and higher-quality prints. Thus, it is generally recommended to keep the starting point for PLA print speed around 40-60 mm/s.

However, experimenting with different speeds is critical to find the best print quality and speed balance for your specific printer and filament.

Depending on your printer, you can take the printing speeds to a different level with some mods and upgrades. With this, you can print comfortably even at 200 mm/s without compromising quality.

Retraction

Stringing and oozing can be common issues when printing with PLA. To minimize these issues, adjusting your retraction settings can be helpful. Retraction is when the extruder pulls the filament back during non-printing moves to prevent over-extrusion.

The process’ efficacy depends on two variables: distance and speed, and tweaking these should be enough to fine-tune your extruder’s retraction. However, such factors differ slightly depending on which type of extruder you’re using: direct drive or Bowden.

So, it is best to adjust the settings according to your particular printer, extruder, and filament, which you can determine by printing a retraction test.

Typically the direct drive extruder’s retraction speed is between 40-60 mm/s, and the retraction distance is 0.5-1.0 mm. Similarly, the Bowden extruder’s speed ranges between 30-50 mm/s, and the distance is around 5 mm.

Part cooling fan

A part cooling fan operating at full speed during the printing process is critical for PLA. This lets layers quickly cool and solidify while maintaining a desired shape.

One thing to keep in mind is that the fan should be off during the first couple of layers which allows for proper bed adhesion. After which, the fan should run at maximum speed until the printing process completes.

Best PLA filament for 3D printing

The availability and choices for PLA filament out there are almost endless. Therefore, when searching for the best PLA filaments for 3D printing, it’s crucial to consider factors such as application, quality, consistency, and affordability. So now let’s look at some of the best PLA filaments on the market today.

HatchBox PLA

Hatchbox PLA filament is a popular choice among makers because it provides a high-quality product at a low cost.

In addition, the quality of the same color and material tends to be consistent across multiple spools. As a result, HatchBox PLA is becoming more widely known and respected in the 3D printing community.

Hatchbox also has a large selection of PLA colors, as well as special filaments like wood-infused and glow-in-the-dark iterations. It has a total of 68 PLA materials in its 1.75 mm filament catalog, all with different colors, finishes, and textures.

Prusament Clear PLA

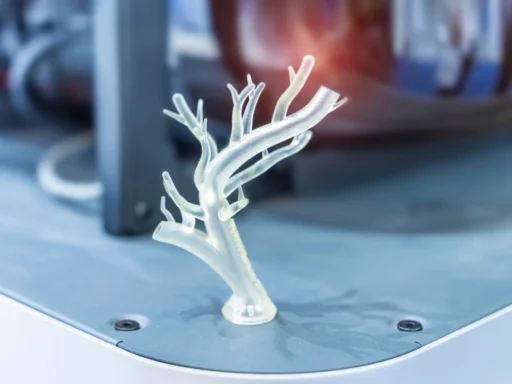

Prusament Clear PLA 3D is a premium filament by Prusa Research that’s especially useful for 3D printing transparent or translucent products.

With this, you can print aesthetic objects with a striking appearance and also practical parts such as covers and protective cases.

Along with clear PLA, Prusa also offers many other filaments compatible with all Prusa 3D printers (along with many third-party ones).

Overture PLA Filament

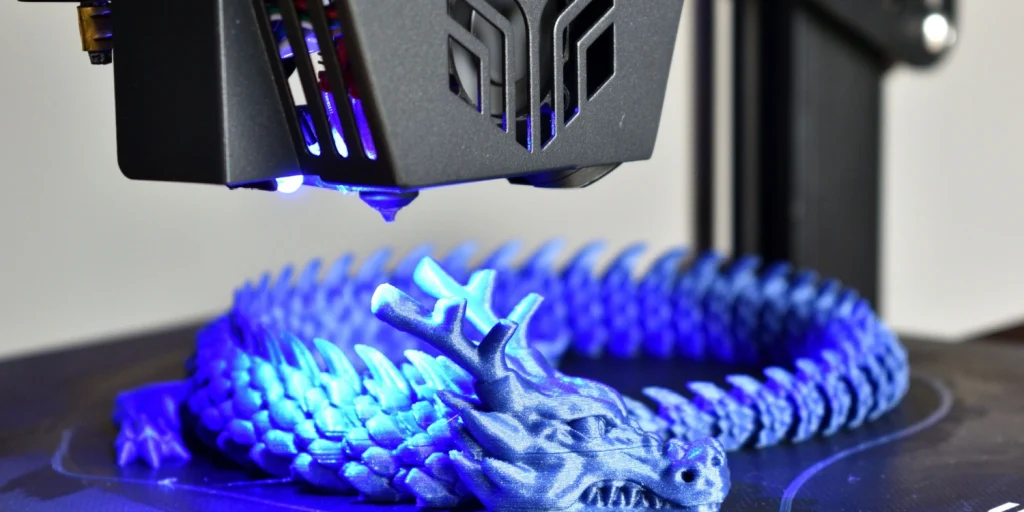

Overture offers a wide range of PLA filaments in various colors and finishes, including rock and silk. It also features a Silk PLA in dual colors, such as Blue-Silver and Purple-Gold, which is great for crafts and decoratives.

Any part you print with this dual-color material looks fantastic both while printing and when it is finished and ready.

Start PLA-ying!

There are many useful and practical things you can print with PLA. After you finish setting up all your slicer settings and print out a few test prints, you’ll be ready to start your first project. A simple yet fascinating 3D printed vase could be an excellent choice for this initial print.

Once you’re ready, set your slicer to vase mode and get printing! You can even print multiple vases using different colored PLA filaments.

Since we are on the topic of filaments, there is a commonly occurring problem with filaments in spools that are currently no longer in use. As a result, the ends of the filament tend to unwind, which can become a hassle sorting it out when you want to use it.

To solve this issue, you can print this useful filament clip. The maker recommends printing it using standard PLA. It prints in a couple of minutes, so even if you lose it, you can instantly print a new one. These are the two of the most popular, easy things you can print straight away using PLA.

Due to reasons like simple properties, convenient to use and sustainability, many users favor PLA over other 3D printing filaments.

While PLA does have some drawbacks, such as low glass transition temperature and challenges in post-processing, its benefits outweigh its limitations. In addition, its affordability and compatibility with most FDM printers make PLA an attractive option for a broad range of applications.

Overall, by following these basic tips and many of the other guides you can find on the web, it’s easy to explore the possibilities of 3D printing with PLA. So get creative and enjoy!