Are you ready to unlock the power of industrial 3D printing?

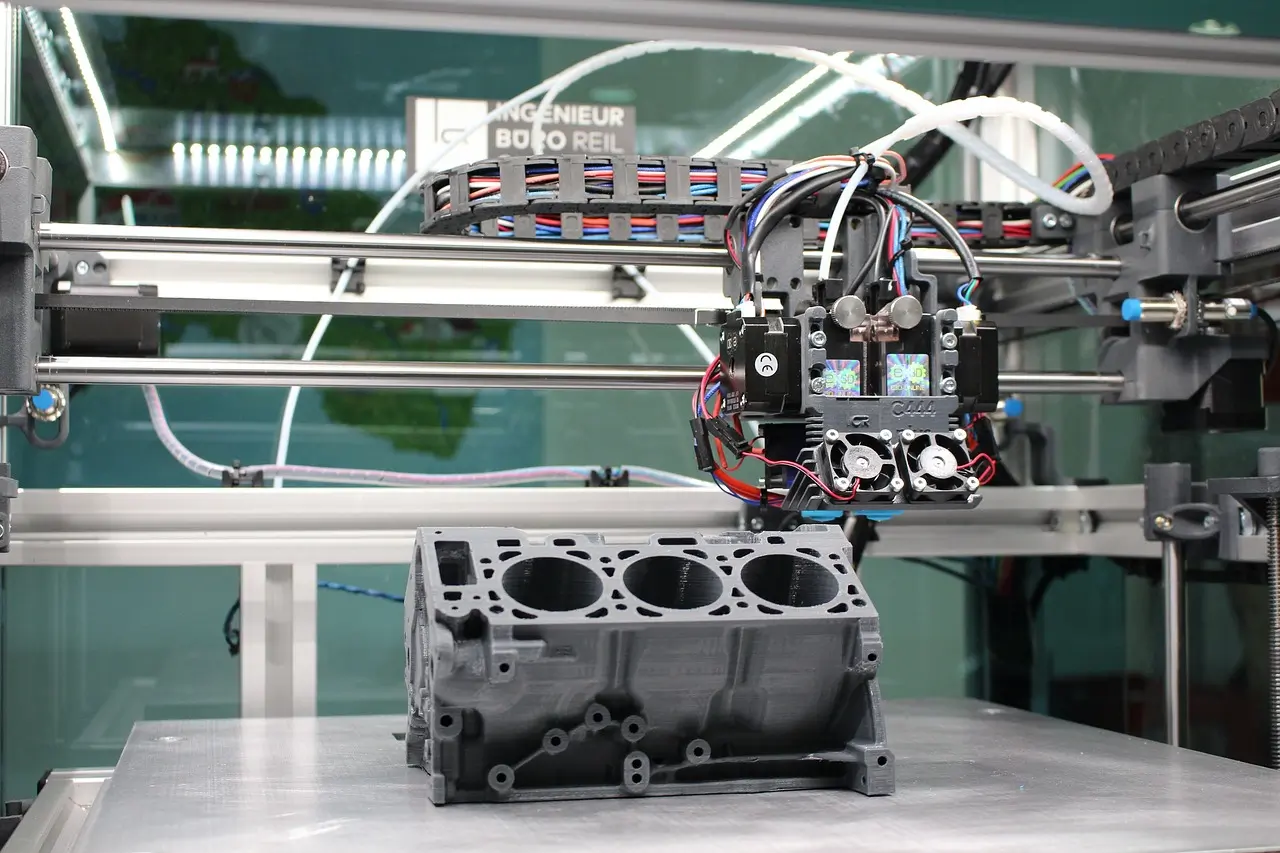

Imagine a world where creating complex prototypes, custom parts, and end-use products was as easy as pressing a button. That’s the reality we live in today with 3D printing, a technology that has revolutionized the manufacturing industry. Industrial 3D printers have advanced significantly in recent years, boasting larger build volumes, faster printing speeds, and a wide variety of materials.

In today’s competitive business landscape, the ability to innovate quickly is crucial for success. With industrial 3D printers, you can streamline your production processes, reduce lead times, and create products with unique geometries that were once deemed impossible. This technology not only empowers businesses to bring their ideas to life faster, but paves the way for sustainable manufacturing by reducing waste and material consumption.

In this article, we’ll guide you through the best industrial 3D printers on the market, with detailed product reviews and real-life use cases to help you make an informed decision. We’ll also offer a glimpse into the future of 3D printing, and what we might expect in the coming years.

So, are you ready to unlock the power of industrial 3D printing and elevate your business to new heights? Let’s dive in and explore the top contenders in the world of industrial 3D printers.

Top Industrial 3D Printers: A Comprehensive Comparison

Stratasys Fortus 450mc

The Fortus 450mc is an FDM printer that’s perfect for businesses looking for a reliable workhorse. It offers a large build volume of 406 x 355 x 406 mm and works with various materials, including ABS, ASA, PC, and ULTEM. With its excellent print quality and resolution, you can produce detailed and durable prototypes, custom parts, and end-use products.

One notable feature is its ease of use, thanks to the user-friendly interface and helpful software. While the initial price point might be higher than some other options, the Fortus 450mc’s long-term value and low maintenance costs make it a solid investment.

Use Case: A great example of the Fortus 450mc in action is the production of customized automotive components for Team Penske: while improving their racing vehicles’ performance. Team Penske, a leading American professional racing team, utilized the Stratasys Fortus 450mc to create customized automotive components for their racing vehicles.

With the Fortus 450mc’s large build volume and material versatility, Team Penske was able to produce lightweight, durable parts that significantly improved their vehicles’ performance. The ability to rapidly prototype and test components allowed them to stay ahead of the competition, showcasing the printer’s value in the automotive industry.

You can read more about this use case here.

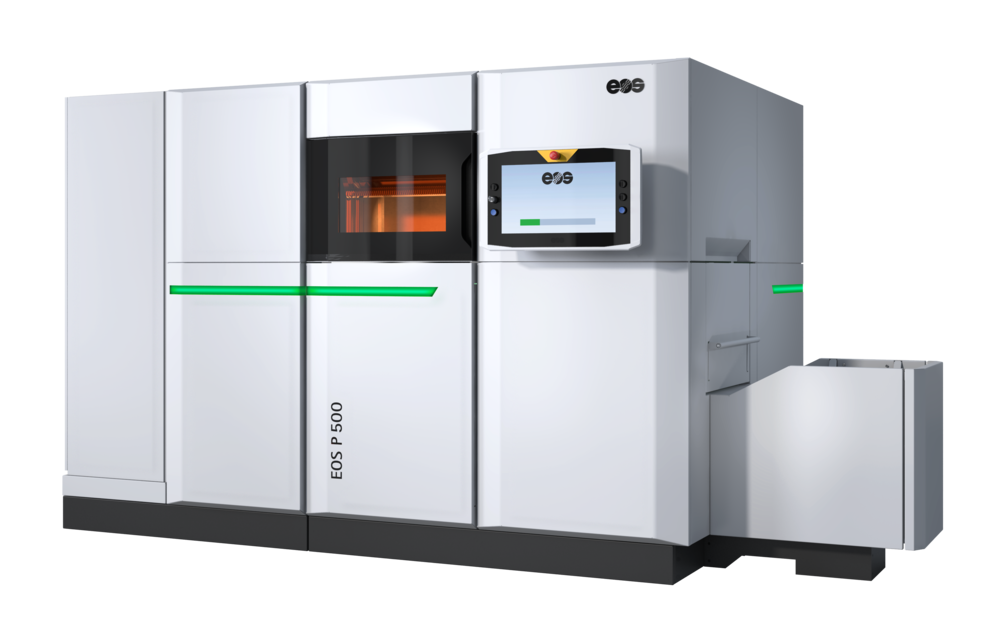

EOS P 500

The EOS P 500 is an SLS 3D printer that excels at creating complex, functional parts. It features a 500 × 330 × 400 mm build volume, high-speed dual-laser system, and compatibility with a variety of materials like PA 12, PA 11, and TPU. Its advanced temperature control system ensures consistent print quality and resolution, making it ideal for businesses that require high-quality, repeatable parts.

The P 500 is relatively easy to use, and while the price point might be on the higher side, its efficiency and capabilities offer long-term value for many industries. Maintenance is also streamlined, thanks to its automated powder management system.

Use Case: Aerospace company ArianeGroup used the EOS P 500 to manufacture a functional rocket engine demonstrator, showcasing the printer’s capabilities in high-stress applications. Aerospace company ArianeGroup collaborated with EOS to develop a functional rocket engine demonstrator using the EOS P 500. The demonstrator highlighted the printer’s ability to produce complex, high-strength parts that can withstand the extreme conditions of rocket propulsion. This successful application showcased how the EOS P 500 can revolutionize the aerospace industry by reducing development time and costs, while maintaining the highest quality standards.

Read more about this use case here.

3D Systems ProX DMP 320

The ProX DMP 320 is a DMP printer that specializes in producing high-quality metal parts. With a build volume of 275 x 275 x 420 mm, it’s perfect for small to medium-sized metal components, like those used in aerospace, automotive, and medical industries. The printer works with a range of metals, including stainless steel, aluminum, titanium, and cobalt-chrome, and offers excellent print resolution.

While the initial cost may be high, the ProX DMP 320’s long-term value lies in its precise results, minimal waste, and reduced post-processing. It’s also relatively easy to use, thanks to its user-friendly interface.

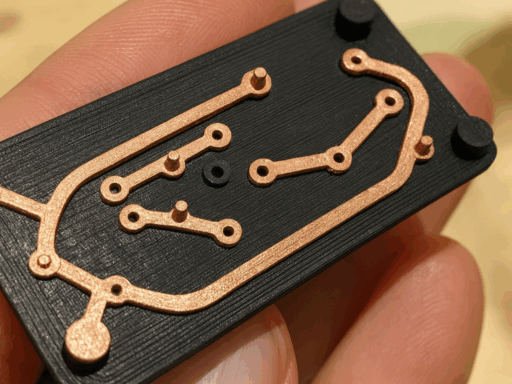

Use Case: Core3dcentres, a global dental manufacturing company, harnessed the power of the 3D Systems ProX DMP 320 to create dental prosthetics. By utilizing the printer’s precision, material capabilities, and excellent resolution, the company was able to produce highly accurate, biocompatible prosthetics with reduced lead times.

This use case demonstrates the potential for the ProX DMP 320 to revolutionize the dental industry, providing customized solutions for patients worldwide.

Read more about this use case here.

Carbon M2

The Carbon M2 is a DLS 3D printer that’s ideal for rapid production of end-use parts with excellent surface finish and detail. It has a build volume of 189 x 118 x 326 mm and can print in various materials like rigid polyurethane, flexible polyurethane, and epoxy. The M2’s unique DLS technology enables faster print speeds and isotropic mechanical properties, ensuring consistently high-quality results.

It’s easy to use, thanks to its intuitive interface, and the price is justified by the printer’s capabilities. Maintenance costs are also manageable, making it a good long-term investment.

Use Case: In collaboration with Carbon, Adidas developed the innovative Futurecraft 4D shoe using the Carbon M2 3D printer. The M2’s Digital Light Synthesis technology allowed Adidas to create a unique lattice midsole that provides optimal cushioning, support, and performance. The shoe’s production process showcased the M2’s ability to rapidly produce intricate, high-performance components for consumer products, revolutionizing the sportswear industry.

Read more about this use case here.

Ultimaker S5

The Ultimaker S5 is an FFF 3D printing solution that’s perfect for professional use across a range of industries. It has a build volume of 330 x 240 x 300 mm and is compatible with multiple materials like PLA, ABS, TPU, Nylon, and more. With its dual extruders, the S5 can handle multi-material printing and soluble support material, offering excellent print quality and resolution.

This printer is very user-friendly, thanks to its intuitive interface, and the price is reasonable considering its capabilities. The long-term value is further enhanced by its reliability and versatility.

Use Case: Audi, the renowned automotive manufacturer, employed the Ultimaker S5 to produce custom assembly tools for their production lines. By using the printer’s multi-material capabilities and excellent resolution, Audi was able to significantly reduce production time and costs for these custom tools. This application highlights the potential of the Ultimaker S5 in streamlining automotive manufacturing processes and enhancing efficiency.

Read more about this use case here.

GE Additive Arcam EBM Q10plus

The Arcam EBM Q10plus is an EBM 3D printer designed for producing orthopedic implants and aerospace components. It has a build volume of 200 x 200 x 200 mm and can process materials like titanium and cobalt-chrome, making it ideal for industries requiring high-strength, lightweight components. Its Electron Beam Melting technology ensures excellent material properties, reduced stress, and minimal post-processing.

While it might be more complex to use than other printers, its capabilities justify the learning curve. The price point is higher, but the long-term value and low maintenance costs make it a worthwhile investment for businesses in the orthopedic and aerospace industries.

Use Case: Stryker, a global leader in medical technology, leveraged the GE Additive Arcam EBM Q10plus to create custom orthopedic implants. The Q10plus’s precision, material capabilities, and Electron Beam Melting technology allowed Stryker to produce patient-specific implants that offered better fit, improved functionality, and reduced recovery times. This case study demonstrates the potential of the Arcam EBM Q10plus to revolutionize the medical industry, providing personalized solutions that improve patient outcomes and overall healthcare efficiency.

Read more about this use case here.

Choosing the Right 3D Printer for Your Business: Key Considerations

Each of these industrial 3D printers offers unique advantages and capabilities for various industries and applications. When choosing the best one for your business, consider factors such as print speed, build volume, quality, resolution, material compatibility, ease of use, price, long-term value, and maintenance.

Additionally, consider your specific industry requirements and budget. As 3D printing technology continues to evolve, more advanced and efficient solutions will emerge, transforming the manufacturing landscape. By carefully considering your unique needs and budget, you can select the ideal 3D printer to enhance your manufacturing capabilities.

Way Forward

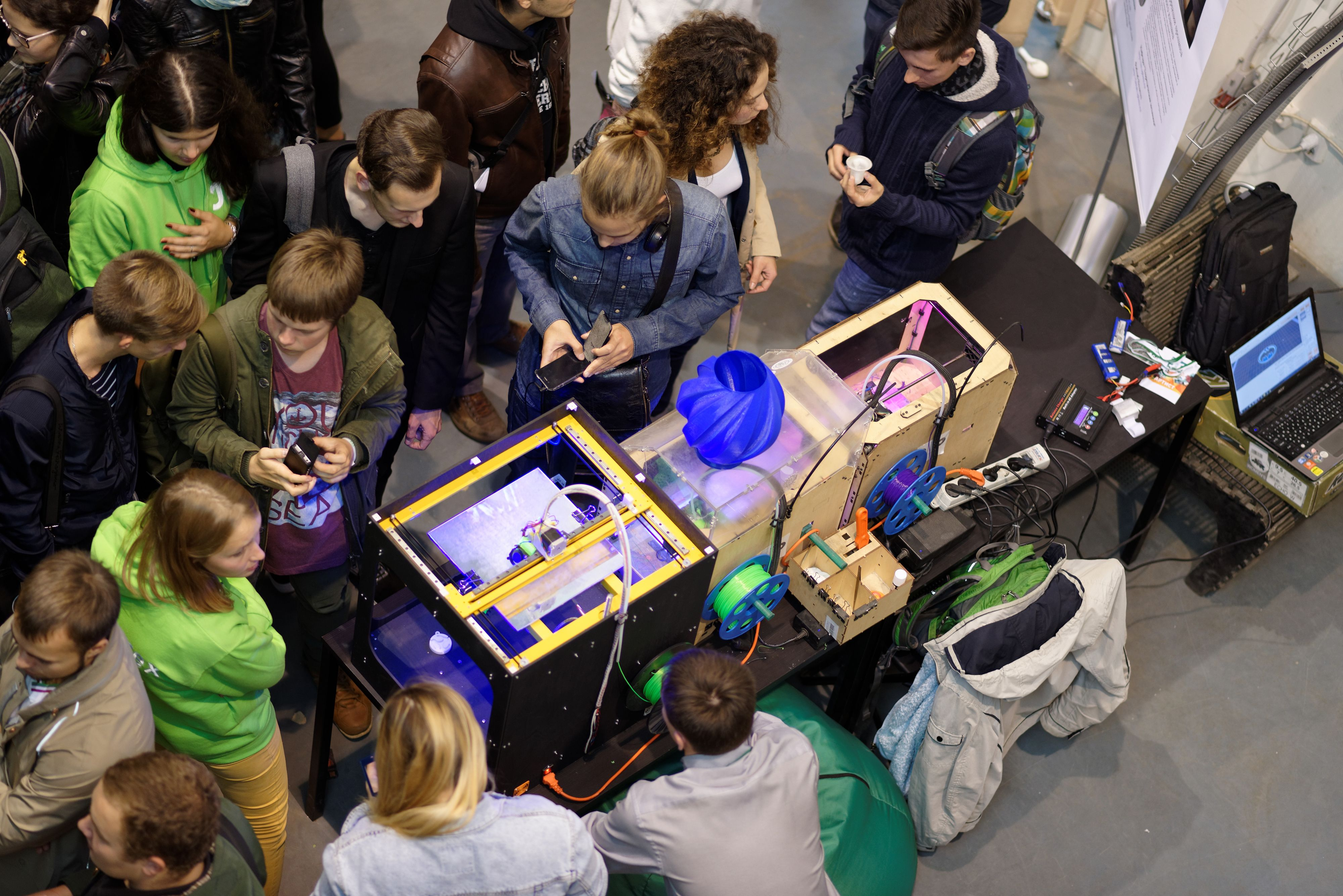

As the 3D printing industry continues to grow and evolve, businesses should stay informed about new developments and be prepared to adapt to emerging technologies. Consider investing in employee training and education to ensure your team is well-equipped to leverage the full potential of 3D printing technology.

Additionally, staying connected with industry experts, attending trade shows, and participating in online forums can help you stay up-to-date with the latest trends and innovations. By embracing the potential of industrial 3D printing, businesses can enhance their efficiency, reduce costs, and ultimately gain a competitive edge in the ever-evolving manufacturing landscape.