So you’ve decided to buy a 3D printer. Congratulations! But, with so many brands and technologies out there, how do you choose the best one for your particular application?

In this guide, we won’t tell you which model of printer to buy – you can be the judge of that! Instead, we’ll equip you with the right questions to ask yourself before making a final decision, and cover some of the key factors to bear in mind along the way.

To begin with, let’s cover which technology you should be looking for, as this will determine the next steps you’ll need to take before making your final choice.

Choosing an additive manufacturing technology

Before you buy into 3D printing, it’s worth taking the time to choose which technology would best suit your needs. As you’d expect from a growing, increasingly disruptive industry, the overall list of 3D printing methods continues to grow, as new ones emerge from the labs and workshops of researchers around the world.

However, if you’re not fully familiar with how each one works yet, that’s absolutely fine. As it turns out, many manufacturing tasks can be carried out with multiple different solutions, albeit with varying levels of success. For instance, if we compare a 3D printer to a car, when you plan to go for out-of-town shopping, it doesn’t really matter if you have an automatic or manual gearbox, both enable the task to be completed.

The important thing is to ‘give you the fishing rod, not the fish.’ So, worry not, we’ll provide you with all the information you need to make the right buying decision.

According to international standards bodies ISO/ASTM, there are seven main 3D printing or AM processes. At the heart of each, is a technology that is marketed under several different brands, but ultimately functions in the same way. These include:

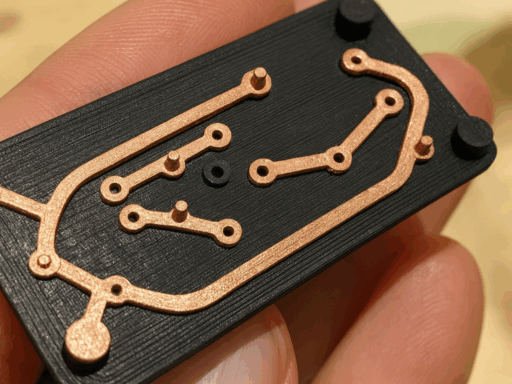

- Material Extrusion: Technologies that squeeze a material (molten thermoplastic) through a heated nozzle and onto a build plate, layer by layer. Fused Deposition Modeling (FDM) and Fused Filament Fabrication (FFF) fall under this category, making it the most widely used 3D printing technology.

- Vat Polymerization: The process of a photopolymer resin being exposed to certain wavelengths of light and becoming solid. The Stereolithography (SLA), Direct Light Processing (DLP), and Continuous Direct Light Processing (CDLP) additive manufacturing processes all fall under this category.

- Powder Bed Fusion: These technologies use a heat source to induce fusion (sintering or melting) between the particles of a plastic or metal powder one layer at a time. Selective Laser Sintering (SLS), Electron Beam Melting (EBM) and Multi Jet Fusion (MJF) can each be categorized as PBF. The Selective Laser Melting (SLM) and Direct Metal Laser Sintering (DMLS) 3D printing processes also deploy a similar approach to selectively bind metal powder particles.

- Material Jetting: Technologies such as PolyJet and ColorJet use UV light or heat to harden photopolymers, metals or wax, building parts one layer at a time. Other kinds of material jetting include Nanoparticle Jetting (NPJ) and Drop-on-Demand (DOD).

- Binder Jetting: This process sees an industrial printhead deposit a binding agent onto thin layers of powder material. Unlike the other 3D printing technologies on this list, binder jetting does not require heat to achieve material fusion.

- Direct Energy Deposition: ‘DED’ creates 3D objects by melting powder material as it is deposited. It is mostly used with metal powders or wire and is often referred to simply as ‘metal deposition.’ Laser Engineered Net Shape (LENS) and Electron Beam Additive Manufacture (EBAM) also fall under this category.

- Sheet Lamination: These technologies rely on the stacking and lamination of thin sheets of material to make parts. There are a few different types of lamination to choose from: bonding, ultrasonic welding, or brazing.

As you can see below, not all AM technologies are available in every class of 3D printer. This is why it’s important to choose a technology before deciding which system to buy.

| Personal | Professional | Industrial | |

| Material extrusion (FDM/FFF) | + | + | + |

| Vat polymerization (SLA, DLP, LCD) | + | + | + |

| Powder bed fusion (SLS, DMLS & SLM) | – | + | + |

| Material jetting (MJ) | – | + | + |

| Binder jetting (BJ) | – | – | + |

| Direct energy deposition (LENS, EBAM) | – | – | + |

| Sheet lamination | – | + | – |

The reason for this ‘inequality’ is that not all technologies provide the same simplicity and low cost as today’s desktop 3D printers, and not all can achieve the performance of industrial machines. Professional 3D printers, on the other hand, offer something inbetween, and often feature short-run production capabilities at relatively affordable prices. As such, it can be said that there is a diversity of opportunities out there.

After you know which technology can meet your manufacturing needs – whether it is for modeling, prototyping, or full-on production, we can move on to the next step: choosing the printer! Yes, that’s right! Here, there are three routes that you can take.

Choosing a class of 3D printer

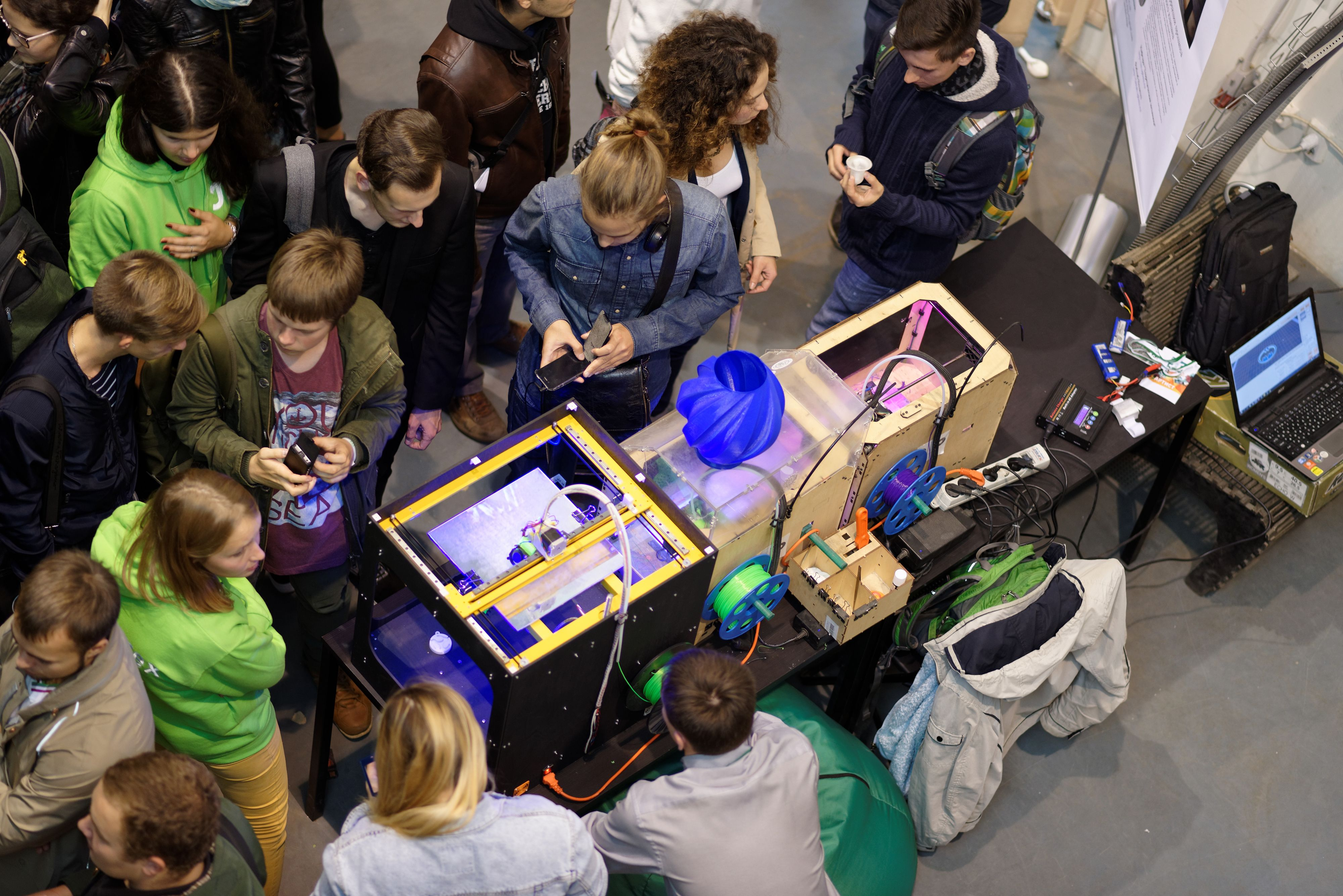

If you google the term “3D printers,” you’ll see that they can take all shapes and sizes, and come with a broad range of price tags, varying from affordable DIY 3D printing kits to industrial machines that can be worth millions of dollars. However, all 3D printing or ‘additive manufacturing’ (AM) devices can be broadly divided into three main classes, each coming with its own production capabilities and limitations.

- Personal or home 3D printers – designed for individual use at a desktop, without needing any adjustments to the room or workshop they’re based in.

- Professional – flexible printers built for engineering and design tasks, as well as those that involve producing end-use parts in small numbers. They could be found in an office or a workshop, just as easily.

- Industrial – 3D printers purpose-built for deep integration into industrial manufacturing setups. Designed for heavy workload and round-the-clock work if necessary. Typically, this group of devices has special room requirements.

Check out our Personal, Professional, and Industrial 3D printer articles for more information about how to go about choosing which system to buy in each category.

Summary

As you can see, it’s not that simple to choose the right 3D printer without knowing the precise application it’s going to be used for, the quality and throughput you’re looking for, the skills that’ll be needed to operate it, and many other factors. Choose the wrong class of equipment, and you could quickly find yourself with an expensive paperweight.

For example, if you were to buy a personal 3D printer for manufacturing applications, you’d likely become disappointed very quickly. Of course, it’s possible to set up print farms of desktop machines for this purpose, but if you want to create products in industrial quantities, there are better-tailored machines out there.

The same can be said of professional-grade 3D printers, which can sometimes produce very high-quality results, but may be pushed to the brink of failures by over-exertion.

To help you choose the right 3D printer, we’ve collated the key features of each type in the table below. Perhaps, after ticking all the right boxes, you may realize you need to increase your budget (or indeed, reduce it) depending on the task at hand.

3D printing categories: At a glance

| Features / Class | Personal / Desktop | Professional | Industrial |

| The main purposes of using a 3D printer | Hobby, training, DIY projects, small repairs, services, school/kids projects | Prototyping, R&D, testing materials, specialized services | To switch from a traditional serial manufacturing method to additive manufacturing |

| Cost of a 3D printer | Low

(< $2,500) |

Medium – High ($2,500-$20,000) | High

($20,000+) |

| Capabilities/Performance of a 3D printer | Very low or low (not more than 1 kg per day/24 h) | From low to medium (up to 20 kg per day/24 h) | From high to very high (up to 50-60 kg per hour) |

| Level of resolution, surface quality, form complexity of a final object | From low to medium (0.2 mm for personal photopolymer printers) | From high to very high (up to 0.05 mm) | From low to high (depends on the production requirements) |

| Size of build area | Small (up to 300 x 300 x 300 mm) | Volumes from a few hundred millimeters cubed up to 1.5 meters or so – depending on the technology | From medium to large – up to several cubic meters |

| Personnel training level required | Beginner to advanced (up to 1 year of experience) | Advanced to professional (2-3 years) | Must meet industry standards |

| 3D printers’s working schedule | Occasional – but can be up to several hours | Able to work continuously without interruption | Designed for round-the-clock operation, often integrated with post-processing machines |

| Cost of consumables | Retail low or medium (for engineering materials) | Medium or high (chipped cartridges) | Low or medium wholesale prices |

| Accessibility of materials | Very accessible, you can by them online | From authorized dealers or specialized suppliers | In industrial volumes under a supply contract |

| Ability to use third-party materials | Usually possible/available | It depends. Sometimes available with restrictions (and with no guarantee of the result) | Must be qualified by manufacturer |

| Facility requirements | None | General service area | Industrial area, strict requirements |

| Power requirements | 220 volt household socket | Single-phase 220 volts or three-phase 380 volts | Industrial 380 Volt up to several tens of kilowatts |

| Security needs | Low (for self-assembly constructor) or medium | High | Compliance with a relevant industrial safety standard |

| Pre-commissioning and maintenance | No commissioning, maintenance is carried out by the user | Done by authorized dealer’s engineer | By manufacturer’s representatives only |

I don’t think the title of your article matches the content lol. Just kidding, mainly because I had some doubts after reading the article.