You may have already read our 3D printer buyers’ guide. If so, thanks for staying with us. If you’re familiar with 3D printing, it was likely just a refresher, but if you’re not fully up-to-date on the technology and missed out, it’s worth tracking back and reading, as this article gets straight to the big question: which Personal 3D printer should you buy?

Whether you call it FDM or FFF, extrusion 3D printing is the most accessible and prevalent technology in the industry. As such, new adopters are faced with the tantalizing prospect of having the widest pool of options on the market. However, this does also present them with the task of having to whittle down these options, and find a system that best meets their model-making needs and desires.

So, let’s start our breakdown from the top, by addressing the straightforward question: what is a Personal 3D printer? – and go from there.

What is a Personal 3D printer?

Whether applied at home or in the workplace, Personal 3D printers are generally designed to be operated by a single user. That said, this isn’t stuck to rigidly by the owners of print farms. As such, we may be categorizing these separately from Professional units, but that doesn’t mean they can’t be deployed in a business capacity.

Likewise, while there are many of the latter that you can easily fit onto your desktop: size is not the key determining factor here. The more important distinction is that Personal printers aren’t built to address specific applications or for use within industrial production, they’re designed for general utilization by designers and makers.

The main characteristics of a Personal 3D printer are:

- The relatively low cost of both the device itself and its consumables.

- They’re compact. They can easily fit on a desk, and have low or medium security requirements.

- You don’t have to make space for them – they can be used anywhere, at home in a kid’s bedroom, in a garage, or in an office – and be powered by a regular 220-volt outlet.

- Often, they have user-friendly, easy-to-use interfaces that don’t require a professional qualification to operate, and come with informative user manuals.

- They don’t require any start-up adjustments, they work out of the box. You can often just install the device, fill up with consumables, and start printing.

- Machine maintenance and the replenishment of materials can usually be performed by the user themselves.

- More often than not, consumables like materials, spare parts, and accessories are also available to purchase freely from online stores (not just licensed resellers), meaning cost-per-part can remain low.

[thumbnail target=”_self” src=”https://www.3dmag.com/wp-content/uploads/pers3dprint-2-1024×576.jpeg”]

Additional categories of Personal 3D printers

- DIY 3D printing kits involve building a 3D printer from scratch. These systems, which have roots in the RepRap movement that began back in the 2000s, are designed for personal DIY projects. Assembling them requires a certain degree of dexterity, but you don’t need a deep knowledge of additive technologies to do so, because they’re fairly simple, and only really have essential functions and capabilities.

With such printers, you can now create quite complex models, but the building and customization process is often seen as more important than the results. We are not talking about high quality and repeatability here. - Desktop, affordable, single-extruder ready-made 3D printers can also be considered a category of their own. They are sold ready-to-go, with no assembly needed, and that is the main difference between this type of printer and DIY kits.

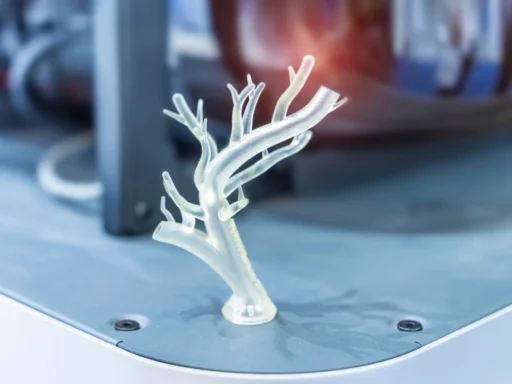

For the rest, everything is the same: only the essential capabilities and consumables are included. Again, this doesn’t prevent these systems from finding slightly heavier duty applications, but they’re more often used to create things like phone cases for personal usage. - The third type of Personal system covers printers used by engineers and designers that are closely approaching the Professional class in terms of capability. These can be SLA or DLP devices working with photopolymer resin, or more advanced desktop 3D printers based on FFF. Additionally, such printers sometimes come with a closed build chamber, and two or more extruders for working with multiple materials.

These are ideal for getting a better grip on how 3D printing works and testing new materials. However, these printers tend to lack the performance, accuracy, and repeatability needed for professional use cases. Printers in this category are often mistakenly classified as ‘Professional.’ While being too expensive for personal/home usage, they are perfectly acceptable for most small businesses.

Personal 3D printers can be used to produce working parts and tooling in short production runs, albeit without meeting the most stringent requirements for quality and accuracy. On the flipside, this hasn’t stopped this kind of manufacturing from being commercialized – the machines are often combined into farms by bureaus providing 3D printing as a paid service.

Examples of such top-level Personal devices include the 3DGence Double P255, Raise3D Pro2, and Flashforge Hunter.

How to choose a Personal 3D printer

If after reading all the reviews you think you need a Personal desktop 3D printer, you’ll then need to go through three steps: (step 1) consider which materials you might need → (step 2) decide on a desired level of accuracy and resolution → (step 3) choose a model of 3D printer with a feature set that meets your requirements.

[thumbnail target=”_self” src=”https://www.3dmag.com/wp-content/uploads/pers3dprint-3-2.jpeg”]

Step 1. Choosing material

Paradoxically, your options in terms of materials are both narrow and broad at the same time. On the one hand, you are limited to two main technologies: material extrusion and vat polymerization. On the other, there is a wide variety of thermoplastic filaments and liquid photopolymers on the market to choose from. The table below provides a rough breakdown of the materials you can print with each type of desktop 3D printer:

| Category of Personal printer | 3D printing technology | Compatible materials |

| DIY 3D printer kit | Material extrusion (FDM/FFF) | PLA, ABS, PETG, TPU, TPE, PP, HIPS, and more |

| Home ‘household’ 3D printer | Material extrusion (FDM/FFF) | PLA, PETG, ASA, ABS,PA, TPU, wood (depending on model) |

| Personal ‘working’ 3D printer | Material extrusion (FDM/FFF) multi-material printing Vat polymerization (LCD, DLP) | All of the above plus photopolymer resins for LCD / DLP 3D printing |

Once you’ve matched the set of materials to your needs, and made sure they are feasible in your price bracket, you can then move on to the next step. For Personal DIY, ‘household,’ and ‘working’ 3D printers, Step 1 is complete.

Steps 2+3. Accuracy and resolution requirements, and choosing the exact model

This step is critical if you’re looking to use a 3D printer for personal work projects. Let’s take a look at the possible requirements:

- If you aim to make high quality models with cleanly cut features and a smooth surface finish, you should look to prioritize resolution over material compatibility and build volume. In this case, look for a desktop 3D printer with an LCD display.

If a system has an LCD resolution of 1920 × 1080 (Full HD), then the camera will often be quite small: just a few centimeters in size. For larger cameras, choose devices with a 2K or 4K resolution.Examples: iSUN LCD 3.0 or Wanhao Duplicator 7 Plus, both with a 2K LCD resolution: 2560×1440. Note: the LCD panel has a limited lifespan, only about 1000 hours. Therefore, if you plan to push your machine to its limits, and not only use it from time to time, we advise you to consider DLP devices.

With systems like the Flashforge Hunter, for example, you can lean on them a lot more, but then they are more expensive – this is an important ratio to weigh up. - If you’re looking to print high density objects with fairly simple geometries, a closed chamber, single extruder system could be right for you. With these units, you can print support structures and the main object using the same material. Their closed chambers also make it easier to deploy materials such as ABS and nylon, which feature increased heat shrinkage, but are much stronger than PLA.

That said, they often yield parts with rough, layered surfaces. To make printed objects smoother, you can choose a nozzle of a smaller diameter, and deposit filaments with a 0.1 mm layer height, though you will have to pay for it with a lower productivity. To avoid this, you can select a printer with replaceable or interchangeable nozzles. One example of such a 3D printer is the Picaso Designer X PRO, but there are a lot of these devices on the market. - If you plan to print complex, multi-material objects, where surface finish may not be your priority, we recommend that you choose a device with two (or more) extruders. These enable you to print a soluble support structure with one nozzle, and the object itself with the other. Printing with dissolvable materials can be a highly effective way of supporting the most difficult-to-reach areas of your part or product.

Dual extrusion 3D printers often feature closed chambers as well, which enable nozzles to be heated to temperatures of up to 500 °C. However, these high-temperature material processing capabilities tend to come at a cost, so be prepared to pay a premium for the luxuries of a dual extruder machine.Examples include the Picaso Designer X PRO, 3DGence Double P255, Raise3D Pro2, and Ultimaker 3. But don’t take this choice lightly: remember, a printer with two extruders is more complicated than a single-extruder one!

[thumbnail target=”_self” src=”https://www.3dmag.com/wp-content/uploads/pers3dprint-4.jpeg”]

When should you buy a Personal 3D printer?

So, which route to take is only up to you. You can often buy Personal 3D printers directly from manufacturers, without needing a ‘face-to-face’ demo. But you always read up the reviews of other users, to get an idea of how machines will perform. We recommend making a choice based on your budget and intended application. If you’re buying one for your bedroom, does it need industrial-grade production capabilities?

Another thing worth paying attention to is interface and documentation, as units geared towards accessibility and with broad language compatibility are likely to be easier to adopt. This will be especially the case if you are just starting to learn about 3D printing. If this is the case, don’t forget to stock up on materials, so you don’t run out mid-print. Also, start by downloading some basic models from popular file sharing sites, then move on to the more complex models as you learn more.

However, if enough time has passed and you realize that you need a printer capable of producing complex parts with a high surface quality from multiple materials, you may have to stretch your Personal machine to the limit. In which case, maybe it’s worth considering a Professional-grade one instead.

If you’re weighing up upgrading, you can find our Professional 3D printer buyers’ guide and Industrial 3D printer buyers’ guide elsewhere on our website.

Here are the situations in which we recommend you buy a Personal 3D printer :

- When you have little or no working knowledge or experience with 3D printing, and are just looking for a way to get a better understanding of how it works.

- When you have a limited budget and you want to print models at the lowest possible cost and initial investment.

- When you want to be flexible and independent with your choice of materials, and be able to buy them anywhere.

- For home use, for yourself and/or children (high school or college students with basic skills in electrical tools or devices).

- Creating models for your own entertainment, and on occasion, those designed for resale in short production runs.