In the world of industrial manufacturing, 3D printing is increasingly disrupting traditional workflows, by offering a more customizable, potentially sustainable alternative. While many of these machines lag behind on throughput, they’re still able to churn out hundreds of thousands of end-use parts per year, making them a genuinely viable option for many heavy-duty manufacturers.

However, such systems come with a huge price tag, so choosing the wrong one can come with significant consequences. So, how can you choose which is the best Industrial 3D printer for your application?

If you’re not already familiar with how the most popular 3D printing technologies work, check out our 3D printer buyers’ guide. If you’re satisfied with acquiring short-run production capabilities, then you may find our guides around Professional 3D printing and Personal 3D printing more helpful, but neither can hit the output of Industrial units. So, which Industrial 3D printer should you go for? Read on to find out.

What is an Industrial 3D printer?

In some ways, the category of Industrial 3D printer is the easiest to distinguish. Where it’s more difficult: determining when it’s time to switch from a Professional to an Industrial-grade system. This can only happen when you’ve clearly defined where 3D printing lies in your manufacturing process, and where it can be used economically at scale for serial prototyping or end-product manufacturing.

Due to their sheer size and high productivity, keeping them loaded with huge bags or drums of material can be an expensive task. The cost-per-print of such machines, whether they be used to create blanks, tooling, or end-products, can also be higher than those of Personal or Professional-grade alternatives. However, depending on the application, overall costs can come in under those of traditionally manufactured goods.

Likewise, the subtractive nature of 3D printing makes it more ergonomic with materials, and when integrated into wider workflows, the technology can help drive down lead times too. All these potential benefits come with significant caveats, which mean they rely on how a technology is applied in a given industry. But, each successful application does have one thing in common: it’s economical. These pricey, heavy-duty units ultimately have to pay for themselves, so this is a prerequisite for adoption.

The main characteristics of an Industrial 3D printer are:

- The high cost of the device itself.

- They often feature large build volumes, need running in accordance with strict safety protocols, and require company access for operation.

- Designed for use in a workshop or on a factory floor where issues like climate, vibrations, and dustiness have all been taken into account. Typically, they require a three-phase power supply of 380 volts, but energy demands can rise to tens of kilowatts.

- Operators should be highly skilled, qualified, and ideally experienced. It could be said that running an Industrial 3D printer is closer to controlling a CNC machine than it is to desktop 3D printing, but both can be helpful training exercises.

- Machine commissioning, maintenance, and replenishment need to be performed by a certified service engineer or regional representative. These types of services are often formalized as part of supplier agreements – but however they’re agreed on, they are a must!

- Consumables are supplied in bags, barrels, and buckets – in industrial quantities. It’s also unlikely that you’ll be able to find and buy them on the open market. In fact, a material supply contract is often drawn up as machines are bought (and sometimes even before). Ideally some of this feedstock will be reusable, but this is by no means common practice in the industry.

Additional categories of Industrial 3D printer

- Specialized enclosed 3D printers can be considered a subcategory of their own. They tend to be designed for performing one specific process, just very efficiently. For example, devices for direct sand mold making in the foundry industry. If the equipment is set up properly, it can be possible to unlock astronomical savings, and reduce product lead times from weeks or months down to a single day. Examples of highly specialized industrial 3D printer manufacturers include Desktop Metal, voxeljet, and FHZL.

- Many of the other systems in this area can be covered under the Industrial 3D printers for general use umbrella. Unlike similarly flexible Professional systems, they tend not to have as broad a material compatibility, as this is limited by economic and production feasibility. As such, when we talk about this category having ‘wide’ potential use cases, we mean it in the literal sense – they tend to be massive! Thanks to their extremely large build chambers, which can be several meters across on each axis, they’re able to print everything from model rigging and assembly slips, to end-use spares for other industrial equipment – whatever is needed at a given moment.

The breadth of an Industrial 3D printer’s applications therefore has an application-specific element, as well as depending on demand territorially. Machines in this sub-category straddle a number of technologies, ranging from the FGF systems of JuggerBot 3D to the Atlas PBF machine developed by GE.

How to choose an Industrial 3D printer

Choosing an Industrial 3D printer can be easier than sifting through other categories of machine, just because of the relatively limited choice. However, the level of risk in buying badly is also much higher. There is no room for experiments here, and the main criteria for success is a positive economic outcome. Usually, suppliers or manufacturers are more than happy to help carry out feasibility studies, which show whether an Industrial 3D printer will work in a given application.

However, how do you know if you need a highly specialized piece of equipment or a more widely applicable Industrial 3D printer? Generally, this requires you to take stock of your own manufacturing capabilities. Do your current systems create the same product as an Industrial 3D printer? If so, how could they be improved upon?

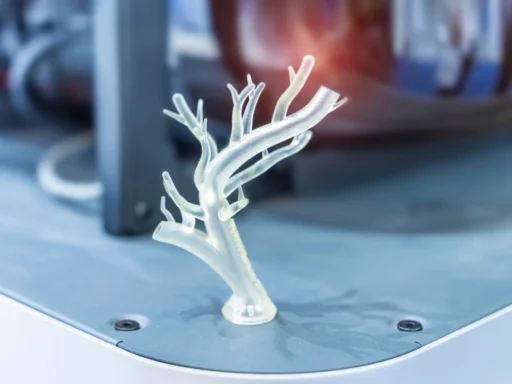

More often than not, 3D printing unlocks a level of customization that traditional manufacturing technologies cannot match. This could mean that certain product geometries can only be achieved with additive manufacturing. But if the output is comparable, throughput, lead time, and cost-per-part can be important differentiators when it comes to making a buying decision. If you can make products with subtractive technologies, these may also be worth weighing up.

Key PointOften, workshops will be fitted with CNC machines as well – the technologies aren’t mutually exclusive after all!

If you’ve carried out all the necessary due diligence, and found that you can create parts with the properties needed via 3D printing, (for example porosity, flammability, or corrosion resistance), then Industrial machines could be ideal. Especially if you’re not targeting millions of parts, but tens to hundreds of thousands per year.

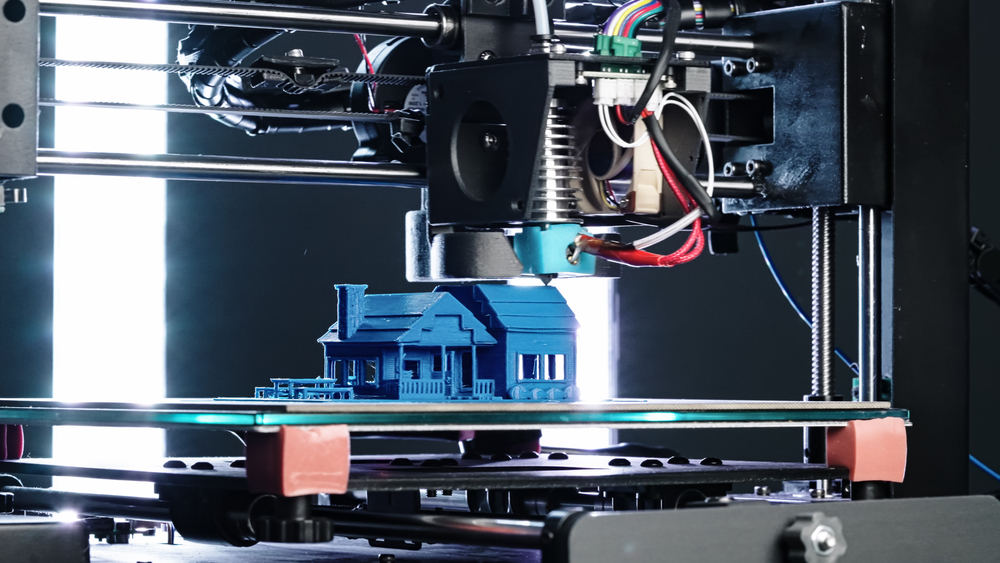

In cases where throughput, product design, and material demands are likely to vary, it may be best to go for a ‘general use’ Industrial 3D printer. For example, with the BOX by BLB Industries, users can make hydraulic structures from water-resistant plastic, pattern equipment (molds) for casting, or create assembly slips from carbon-filled polyamide.

Additionally, tooling manufactured with machines like this can sometimes be ground back into pellets and reused. As large-format, high-throughput 3D printing continues to advance, so does its efficiency and range of applications. Many Industrial systems are now hybrids, for instance, meaning that they incorporate subtractive technologies like CNC machining for post-processing – and these steps forward have seen heavy hitters like Ford, Airbus, Boeing, and more, continue building out their production capabilities.

When it comes to the process of identifying ancillaries for Industrial machines, it can be said that this looks similar to that of choosing a highly specialized Professional 3D printer. The decision will ultimately be made with the needs of your specific production process in mind, together by the manufacturer/reseller, installation team, and buyer.

Such equipment is not cheap, and only a deep understanding of where it would fit into your workflow will do. Test prints are also a necessity, as you can use these to trial the exact production materials and machine you plan on adopting. Elsewhere, you’ll need to weigh up other long-term costs such as installation space, training, (where needed) material qualification, and meeting industry-specific standards. It’d also be advisable to arrange the maintenance of Industrial 3D printers well in advance. Don’t forget, these are high-throughput machines – downtime is unacceptable!

Last but not least, a long-term contract for the regular supply of consumables with clear commitments in terms of delivery, is a vital prerequisite to acquiring an Industrial 3D printer. The supplier and manufacturer of these may be the same, or they could be completely different, but sourcing materials locally can be beneficial, both in ensuring constant supply, and getting them at the best possible price.

When should you buy an Industrial 3D printer?

Given the sheer amount of due diligence that goes into choosing the right Industrial 3D printer, these are no doubt the trickiest category of system to buy. But there are a whole host of things you can do to make life easier for yourself.

First of all, it’s vital to have a clear idea of where you intend to use Industrial 3D printing and how the technology will benefit your business, before you acquire a machine. It’s also worth considering where the system can be installed on your premises, as these are generally hefty pieces of equipment.

Once you have identified the ideal technology for addressing your particular application and set out your budget, it’s then worth reaching out to the manufacturers/resellers of machines that meet your criteria. Doing so will allow you to take advantage of their often-extensive industry expertise, and get hold of prototypes made with any machine you may be weighing up buying.

Lastly, when you’ve identified a make, model, and manufacturer that you want to work with, make sure you organize things like training, installation, and configuration, with your supplier. These machines can take months to ship and install, so having everything ready for when they arrive is critical to getting them operational as soon as possible.

Here are the situations in which we recommend you buy an Industrial 3D printer:

- Acquiring an Industrial 3D printer would provide you with cost, lead time, or design optimization benefits.

- If you have the budget to spend on such a machine.

- When you have secured a regular supply of consumables – and maybe even identified a way of reusing old feedstock for further cost/sustainability benefits.

- When you are ready to allocate a large portion of your workshop/factory and a team of highly qualified industrial workers to the running of such a machine.