If you’re a designer or engineer seeking a more capable machine than your average entry-level desktop 3D printer, good news! You now have a wealth of different options. These cover everything from FDM or FFF extrusion machines to resin-based SLA, MSLA, or DLP systems, but which Professional 3D printer should you buy?

If you’re interested in finding out more about which technology is best suited to a given application, check out our 3D printer buyers’ guide. Alternatively, if you’re weighing up buying a more (or less) capable machine, we’ve also put together guides for Personal 3D printing and Industrial 3D printing. Still with us? Great, then you’re set on acquiring a Professional machine – read on for a full breakdown of the potential candidates.

What is a Professional 3D printer?

This class of printer is the most diverse, both in terms of technologies available and the varying ways in which they’re deployed. In a nutshell, you could say these are machines ‘purpose-built for professional use.’ However, while the very first 3D printers created in the 1980s were positioned as Professional systems, today, this category is more difficult to distinguish. Advanced Personal 3D printers are closing in on Professional machines, and in tandem, Professional printers are getting closer to Industrial solutions.

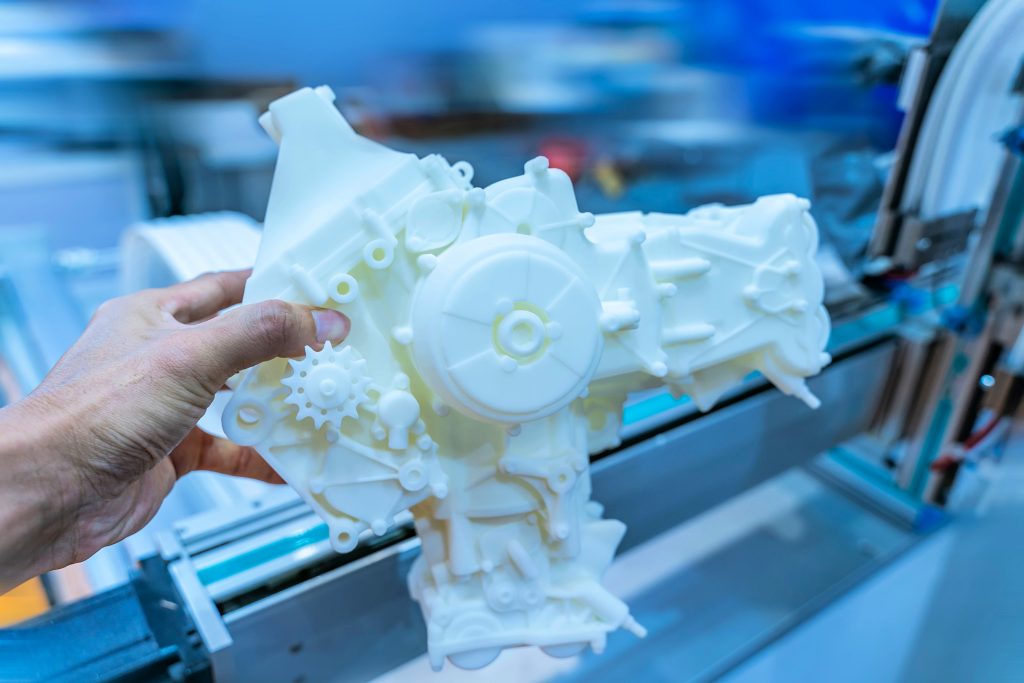

One defining feature of Professional systems is that they’re designed to enable the creation of end-use models, whether that be for production or prototyping. As such, they’re built to handle higher geometric complexity and deliver objects with a better surface finish. Often compatible with higher grade engineering materials as well, these machines allow for the production of mock-ups with properties that closely match those of end-parts – made via both 3D printing and traditional manufacturing.

Compared to Personal 3D printers, you can also expect to spend more, while bearing with slower print speeds than Industrial machines are capable of. With all this in mind, it can be said that the ‘slogan’ of this class is, ‘if you’re looking to create complex parts in high quality from special materials at all costs – buy a Professional 3D printer.’

The main characteristics of a Professional 3D printer are:

- Devices and consumables are likely to be expensive (when compared to Personal machines).

- While such printers can range from miniature to large in size, they all require some level of special access/authorization – an important feature of systems with Professional applications.

- As they tend to be more capable than Personal machines, they often require more space to operate in, and higher voltage power outlets.

- A higher level of knowledge/skills are usually required to run Professional-grade 3D printers.

- Replacement materials are usually acquired via an authorized distributor or reseller. Sometimes, it’s also possible to book other services around installation and the supply of ancillary 3D printing equipment from the manufacturer.

- Some 3D printers don’t allow for the use of third-party consumables. Where units are built around an open-material philosophy, they tend to come with a list of recommended materials and settings for working with them. However, the quality of resulting prints is not guaranteed when working with feedstocks not included in this ‘recommended list.’

- Lastly, while it depends on a range of factors, the cost of a final Professional 3D printed part can drift into the medium-high price range. That said, part quality, complexity, and properties can also reach incredibly high levels, which may make this lofty cost-per-part worthwhile.

Additional categories of Professional 3D printer

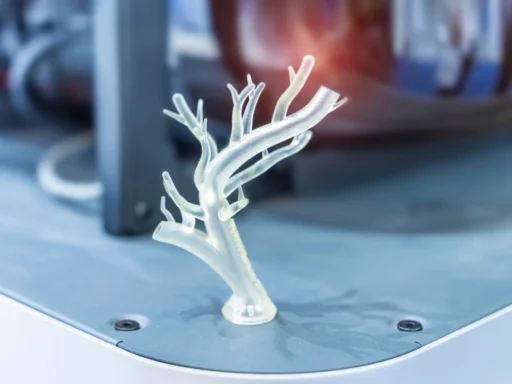

- Highly specialized closed-print chamber 3D printers. This category includes 3D printers for jewelry or dentistry (think brackets and surgical templates). Such devices are Professional and not Industrial-grade for two reasons: you don’t need to make an especially large space for them, and they don’t use materials in industrial quantities. In some ways, they are close to Industrial printers in that they can be deeply integrated into manufacturing processes.

Such printers tend to have closed print chambers, specially made consumables, and sometimes even ‘have chipped’ cartridges, all because of the strict material requirements in certain industries. On the other hand, they can be small and not particularly powerful, one of the main dividing lines between Professional and Industrial systems. One example of a highly specialized professional 3D printer is 3D Systems ProJet MJP 3600W. It’s designed to manufacture jewelry or foundry castings from a proprietary wax.

- Professional 3D printers for prototyping products before they’re manufactured by another means. These could be functional prototypes, designed to imitate the properties of a future product, as well as those made for ensuring the quality of product assembly. These printers are most useful when you need to get a highly accurate, complex prototype that doesn’t need to withstand constant usage.

Full-color printers imitating the look of the future product, in other words, ‘visual prototypes,’ can also be added to this category. Although some remain open-material, users of such machines may not be able to enjoy as wide a choice of feedstocks as other 3D printing adopters. This might not be a massive issue for some, however, and endurance is often not the primary goal during prototyping. Examples of such a printer include the UnionTech Pilot 450, which features an open-material setup that lends itself to various applications.

- Research 3D printers represent another separate subcategory under the ‘Professional’ banner. Often, these machines are used to research the properties of materials. For instance, when you need a highly flexible, rubber-like prototype or one with the flame retardancy needed to make high-temperature gaskets. With such a printer, you can also print with polycarbonate one day, with polypropylene tomorrow, and chemically inert PEEK the day after that.

Though costly, this versatility makes Professional 3D printers especially useful to business adopters. Even the most experienced designers may be shocked at the results you achieve with mid-tier 3D printers these days. A good example of this type of Professional 3D printer is 3DGence’s INDUSTRY F420. Thanks to its heated chamber and three interchangeable printheads, it can draw on various high-temperature materials to create parts with greater resistance qualities.

- We consider the last category of Professional system to be 3D printers with large build chambers, where the sum of the width, length, and height is equal to two meters or more. The main difference between these and Personal 3D printers is that they cannot be placed on a desk. The pricing is higher than the cost of desktop printers too.

This is due to the technical design problems that need to be overcome when increasing dimensions – the frame must be rigid, and the performance high, otherwise 3D printing will take too long to be an effective manufacturing tool. If you make the linear dimensions of a machine twice as large, for example, its volume, weight, and product lead time jumps by 800%. If you’re looking for a large-format Professional 3D printer, the BigRep ONE is a great example.

How to choose a Professional 3D printer

Choosing a Professional 3D printer can be challenging due to the sheer variety of materials and technologies available. You can do almost anything with such printers, however the nuances lie precisely in the word ‘almost.’ You can create parts with almost perfectly smooth surfaces, almost exact tolerances, and theoretically at least, almost the maximum possible levels of strength and hardness.

To help you cut through the noise around Professional 3D printers, and select the system that best suits your individual needs, we’ve put together a handy walkthrough guide. The way we see it, this process should always follow four key steps: 1) choose from the available technologies -> (2) identify which materials you might need → (3) decide on your accuracy and resolution requirements → (4) select a model.

Sounds easy, right? Well, not necessarily. Each category of Professional printer does have its own nuances and foibles. Let’s take a deeper look at them, as we walk through our buyers’ guide, step by step.

- Choosing a highly specialized Professional 3D printer

Here you are not just choosing a printer, you’re choosing a complete technological solution for your specific industry, for example, jewelry or dental production. In this case, the technology behind the 3D printing process and industry-specific safety standards will dictate the materials that can be used. Adopters of such machines tend to have little room for experimentation. They have to work first time and every time. As such, buying from a Professional integrator/reseller/provider who specializes in supplying manufacturers in your industry, is often seen as the safest option.

With resellers you can also ask for all the technical documentation you may need, get a detailed description of how a given technology works, and tap into the knowledge of their previous customers. If the process of doing so requires you to go abroad, it might well be worth it, because the cost of a mistake could be huge, due both to adoption costs and potential loss of business; technically incompatible or non-compliant machines are no good to anyone. As a result, background research and consultations may seem like a waste of time, but they’re definitely worth it.

So, while not the only correct way to choose a highly specialized Professional 3D printer, the safest way to do so is to contact the manufacturer of a machine you like.

- Choosing Professional 3D printers for prototyping and modeling

Those looking to 3D print product prototypes in particular, face a similar choice to manufacturers with industry-specific requirements. The only real difference being that prototyping systems can often be used without having to worry about sourcing materials, and rely solely on the ones supplied by the manufacturer. In some senses it’s better this way, as results are more predictable.

Of course, when it comes to the R&D of new materials, you’re going to need an open-material 3D printer. So, there will be situations in which you need to make decisions ad-hoc. But the important thing is to decide which materials you plan on working with first, then choose one (or several) of the seven technologies mentioned in our introductory article.

It’s also important for manufacturers to decide what they’re testing for during prototyping: ease of assembly, strength characteristics, thermal or chemical resistance, or replicating the appearance of a final product? The same is true if you are not going to make prototypes, but the parts themselves such as tooling, from a wide variety of materials. Either way, answering the question: ‘What’s most important to me?’ should get you moving in the right direction.

The next stage of the selection process is the most important. You need to evaluate the capabilities of selected technologies to handle the required geometry of your prototypes or production samples.

Once you’ve checked through all the technologies with your design requirements and weeded out all the ill-fitting options, you end up with one (woo-hoo!) or maybe just a few technologies that could work. If your mind is still not made up, consider cost-efficiency. Another important aspect that’s worth thinking about, is the prospect of technological development: could the emergence of new materials with previously inaccessible properties broaden the applications of your printer in future? Quite possibly.

After all these factors have been taken into account, you can take your preliminary technology choice to a reseller capable of helping you with finding a system model and manufacturer that works for you. Devices of such grade cannot be bought online or in-store. As a result, we recommend visiting a showroom or a site where your chosen 3D printer has been installed, ordering a test print, and carrying out a detailed calculation of its costs. Also make sure to ask about the procedure for ordering and purchasing consumables. Discuss the delivery timeline, it can be up to six months for remote replenishment. Also discuss the setup/commissioning work, support and routine maintenance. In our experience, the full supply cycle of a Professional 3D printing device can take up to a year.

3) Choosing large-format Professional 3D printers

Once again, by ‘big’ here we mean a chamber with the sum of the width, length and height equal or more than two meters in size. This criterion leaves you with only two available groups of technologies: extrusion and UV photopolymerization. From there, the choice is generally quite simple – if you need parts with a very high accuracy and smooth surface finish, but don’t mind spending substantial sums of money on expensive resin, choose SLA, MSLA, or DLP.

If your budget is tight, and you don’t want to spend too much on materials, choose FDM or FFF, but be ready for time-consuming post-processing – grinding, tumbling, or painting. Why? Because the surfaces of extrusion printed objects are layered, and the thickness of one layer can reach 1 mm, which is quite noticeable.

When should you buy a Professional 3D printer?

Hopefully the above breakdown helped, but let’s round-up our top tips, just in case you got lost along the way. When should you buy a Professional 3D printer then? Well, these machines are designed for running 24/7, not at-home experimentation. They’re not cheap, so you’ll need to have tens of thousands of dollars in hand, to make a quality purchase. However, if you’re making a product that couldn’t possibly be manufactured any other way, this could be worth it!

Elsewhere, if you’re planning to experiment with materials, the open-material nature of many Professional machines is likely to be appealing to you. Ensuring that you have the right personnel to operate these systems is also an important aspect worth considering. If you have a skilled maker in-house who has outgrown their pet projects at home, they could fit the bill, but often they need running (fittingly) by trained professionals.

If you’re weighing up upgrading, take a look at our Industrial 3D printer buyers’ guide, or if these systems seem a bit demanding or expensive, you can also find our Personal 3D printer buyers’ guide elsewhere on our website.

Here are the situations in which we recommend you buy a Professional 3D printer :

- When you aim to create a highly complex, custom part that couldn’t be made any other way and the floorspace to accommodate a large machine.

- You have the budget needed to meet the relatively high initial cost of machine adoption.

- When you have identified which materials you need to manufacture with.

- You know the benefits of the 3D printing technology you’re looking to buy into.

- You have carried out your due diligence and identified a supplier capable of meeting your manufacturing needs.

- At this resellers showroom you have had the opportunity to ask questions and order samples. Do not skimp on this: you don’t want to buy an expensive paperweight!