What would you say if you were moving into a house that was printed in just 24 hours? What if this house was meteor-resistant and located on Mars? Now, it may sound like a scene from a slightly implausible sci-fi movie, but chances are that these possibilities will soon be offered by 3D construction printing (3DCP).

Humans have come a long way since building their first shelter by simply putting several rocks on top of each other. Constructing modern houses is time-consuming, noisy, expensive, requires much skill, hard manual labor, and heavy equipment. On top of everything else, it produces an inexcusable amount of waste. With about 1.6 billion people living in substandard housing and 100 million homeless, the global housing crisis is fueled by soaring property prices and the fact that often houses simply can’t be built fast enough. Needless to say, the world is ready for an alternative, which several 3D construction companies are working hard on.

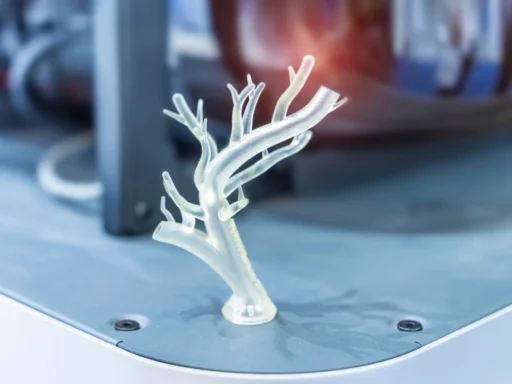

Different technologies that use 3D printing as their main method to create buildings or construction components go by the name of 3D construction printing, or additive construction. Widely applied in private, commercial, and industrial sectors, the method employs such 3D printing technologies as extrusion, additive welding, different types of powder bonding, and more. The advantages of this alternative approach include reduction in time and cost, possible DIY construction, improved accuracy, and less waste. All this was enough to make 3D printed houses the next big thing, and since 2014 the world has welcomed more and more 3D printed structures. (Editor’s note: While we wish it had already truly taken off, it’s not every day you’re invited to a 3D printed home, and the concept remains a novelty. Still, we’re excited to see where we go from here!)

Back in 1995, when Behrohk Khoshnevis, professor of engineering at the University of Southern California, came up with a technique he named Contour Crafting, little did he know it would set the idea of 3DCP in train. Khoshnevis suggested an extrusion and shaping method for creating a house layer by layer with the help of a robotic system using a crane to do the actual printing.

The early 2000s marked the beginning of exploration for different groups who studied the possible up-scaling of 3D printing in construction. This resulted in the invention of the D-shape technology by Enrico Dini in 2005 and the beginning of 3D Concrete Printing at Loughborough University in 2008. The so-called second generation of 3DCP spans the period of time from 2015 up until now, during which the technology’s capability has taken a quantum leap.

Let’s take a tour of just a few milestones and some points on the map where 3D printed houses have appeared over the last several years.

2017: Yaroslavl, Russia

The very first residential building in the European continent 3D printed for your average family was the brainchild of a group of companies called AMT-SPECAVIA. The home covers an area of 298.5 square meters and consists of 600 wall elements printed in the workshop and assembled on site like Lego. What makes this project truly amazing is that it was unprecedented: a one-of-a-kind design and construction cycle resulted in a real structure, a home to ordinary people like your neighbors.

Another important aspect: it is in full compliance with classic construction procedures, such as getting a permit for building or connecting all engineering systems – the perfect proof that 3DCP can in fact be employed for creating more housing. Fast forward to 2022, AMT-SPECAVIA had started construction of a 3D-printed village with a total area of 1,5 hectare reserved for the houses. The settlement not far from Yaroslavl will include a total of 12 homes with water, electricity and sewerage.

2019: Eindhoven, Netherlands

A perfectly habitable home in the shape of a boulder welcomed Elize Lutz and Harrie Dekkers a short time ago. Printed in 5 days, it is twice cheaper than a comparable dwelling constructed in a conventional way. This single-story house is the creation of Project Milestone, an ambitious partnership between the Eindhoven University of Technology and Vesteda corporation. Their big plan was to hit the rental market with a series of five homes of uncommon design, the architects making each next house increasingly complex.

This first 94-square-meter home was 3D-printed with a massive robotic arm distributing cement layer upon layer through a special nozzle. Additional insulation and connection to the heat grid make the house energy-efficient, and the curved walls give it a cozy, burrow-like feel. In terms of design, the structure is groundbreaking, given the freedom of form the project’s architects can enjoy thanks to 3D printing. The boulder-house is perfectly organic in its forest surroundings, which is also hard to achieve for any modern concrete building of a traditional rectangular shape.

2019: Dubai, United Arab Emirates

The 650-square-meter administrative building in Dubai is the largest 3D-printed building created so far and, frankly, hard to outdo. Manufactured with Apis Cor’s stationery printer, this mind-blowing two-story project is now home to the Dubai Municipality. Apis Cor, a start-up from Siberia, now Florida-based, has a 3D printed house in Russia built in less than 24 hours on their record of achievement. For the structure in Dubai, the printer was working right at the construction site, which allowed Apis Cor to test it in challenging environmental conditions.

Yet another lofty aspiration of Apis Cor is to make space inhabitation possible. In the same year the company teamed up with SEArch+ for NASA’s multi-phase 3D printed Habitat Challenge and designed sustainable shelters suitable for Mars. The project of a living space for five astronauts, exceeding radiation standards and offering a breathtaking view of the Martian landscape won first place in the competition.

2020: Tabasco, México

The US-based non-profit New Story began in 2015, shortly after the devastating 7-magnitude earthquake hit Haiti. With millions of people left homeless, there was a pressing need for technology to quickly rebuild shelters. Five years later, having transformed thousands of lives, New Story collaborated with the tech company Icon to help rural Tabasco combat the housing issues. The plan was to build an entire 3D printed neighborhood for the people living in extreme poverty. The project in Tabasco is a great example of sustainable construction: not only does 3D technology make building faster and cheaper, but locals are hired to do the remaining labor, thus creating additional employment for the community.

The pandemic froze the project for a little while, but it is gradually resuming its pace now. The 3D-printed village is a total of 500 houses, each built from the bottom to top with layers of concrete mix in about 24 hours. Icon’s Vulcan II, the 3D printer used in the project, was designed specifically to address homelessness. Ten of the houses were printed right on site with its help, dozens are now completed and hundreds are on their way. A proving ground for structures of this kind, Tabasco is located right in the heart of a seismic area. The existing houses have already resisted one earthquake showing that 3DCP can be a solution for vulnerable communities that might face natural disasters.

2021: Massa Lombarda, Italy

One of the latest 3DCP achievements is TECLA, a sustainable habitat made of clay in Massa Lombarda (Ravenna, Italy). The name is a compound word from “technology” and “clay”, also inspired by one of Italo Calvino’s Invisible Cities, where never ceasing construction is a metaphor for architecture adapting to environmental requirements. WASP, a pioneering Italian 3D tech, and Mario Cucinella Architects (MCA) created this circular residential building in a revolutionary way, mixing recyclable, biodegradable materials for printing: raw local soil and water.

Crane WASP is an innovative machine used in the project, in fact, several collaborative 3D printers were operating at the same time to build the circular housing model. Taking bioclimatic principles into consideration, nearly zero waste, and locally sourced printing materials mean TECLA is a new word for the next-gen eco-housing.

As all these examples demonstrate, harnessing cutting-edge 3D technologies for construction may well provide us with more affordable houses, new schools, hospitals, and public buildings. As businesses, academia, NGOs, and enthusiasts all over the world are looking for the long-awaited solutions to global challenges, 3D tech keeps testing its limits to offer one. The way we see construction is rapidly changing, and there’s hope 3DCP will be instrumental in eliminating homelessness, and creating homes of the future.

I think it’s great