If you work with 3D technologies, you’ll likely already have heard about 3D scanning spray. After all, it’s rapidly becoming a popular way of ensuring scan data accuracy, especially when working with tricky-to-capture objects.

3D scanning sprays are especially useful for digitizing dark, shiny, and transparent surfaces, but they’re not always a necessity. Using wireless 3D scanners, or those with single-laser settings, you can often tilt to find the ideal surface capture angle. Accuracy can also be maximized with technical trickery and other accessories, so sprays are far from the only solution.

This begs an important question: When should you use 3D scanning spray? If you’re not sure, this breakdown is written just for you. There’s no silver bullet here, and it depends on your project needs, but there are certain things you should know before deciding.

Let’s take a look at the most important factors to consider.

What is 3D scanning spray

Generally, 3D scanning sprays are composed of fine powders or particles suspended in a carrier liquid or propellant. Products’ individual ingredients are less important than the mattifying effect they have on surfaces, which makes them easier for 3D scanners to detect.

Often designed to evaporate after usage, 3D scanning sprays mark closed surfaces without risk of damage. This makes them perfect for digitizing rare, delicate, and expensive items!

When to use 3D scanning spray

With 3D scanning sprays, you’re essentially trying to create a ‘contrast’ on surfaces that makes it easier for 3D scanning devices to recognize.

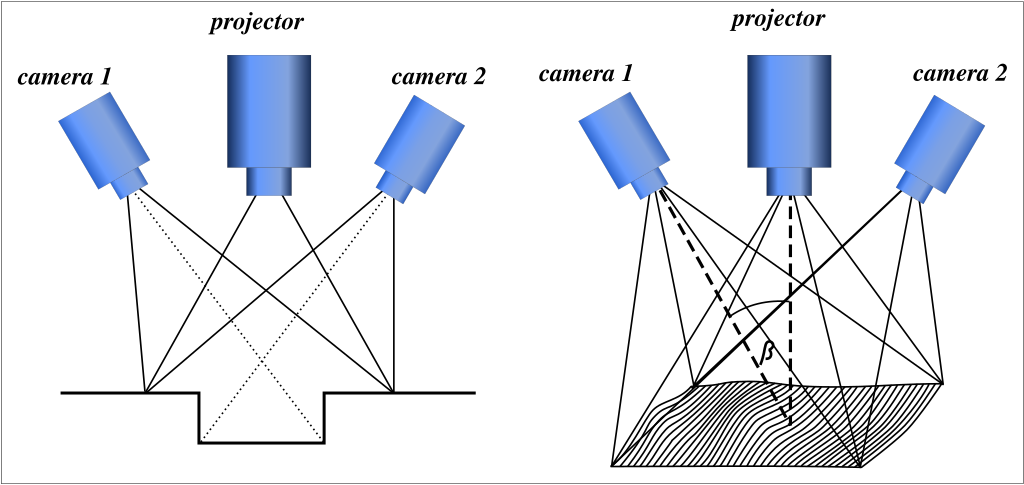

Professional laser and structured-light 3D scanners allow users to rapidly, accurately digitize objects, people, and environments. But optical reflection can occasionally create problems for such devices when capturing certain surfaces – particularly dark or reflective ones, and those with deep pockets that hide features from view.

While transparent surfaces let light shine through, dark objects absorb it, and those made from glossy materials like metal shatter light, resulting in noisy scans. Cavities can also present an issue, disturbing light patterns as they land, leading to unreliable data capture.

Scanning sprays offer a solution to these challenges. Creating an easily identifiable matte surface has been proven to boost visibility, improve accuracy, and enhance results.

How to apply 3D scanning spray

We’ll cover the different types of 3D scanning spray in the next section. But you can generally apply each of them using the following workflow:

- Prepare your object as usual by placing it on a flat, stable surface. Sometimes it’s worth cleaning parts to ensure no other residue will interfere with your results.

- Gently push down on the spray button, applying an even coating from 15-20 cm away. Consistency is key here, as applying too much can impact accuracy.

- At first, all 3D scanning sprays will make your object appear wet. But don’t worry, vanishing and semi-permanent products will dry, leaving behind a coating.

- If this wet look doesn’t disappear in a minute or two, you may be spraying too close to your object. Try backing up and putting more distance between you and it.

- Start 3D scanning as normal. Once you’re finished, the matte effect left behind usually takes a few hours to disappear, but it can be wiped away faster if needed.

Note: Many sprays come with safety conditions. Always read the label before you begin!

Different types of 3D scanning spray

Semi-permanent scanning sprays

When it comes to capturing non-coated metals and thermoplastics, semi-permanent sprays are the way to go. Leaving behind a white powder that makes surfaces easier to detect, these are deliberately designed not to evaporate during lengthy 3D scanning sessions.

Like other 3D scanning sprays, they can be rinsed off or removed with a cloth. As such, they’re not fully permanent. You still don’t need to worry about causing any damage.

Vanishing scanning sprays

Often described as vanishing or ‘sublimating,’ these 3D scanning sprays last up to 48 hours – though this depends on the formulation – some will evaporate in just 15-30 minutes.

Products designed to aid the 3D scanning of small objects tend to evaporate more quickly and leave thinner coatings. Longer-lasting sprays are generally targeted towards complex use cases or industrial applications requiring large coatings, where spray guns may be required.

Where to buy 3D scanning spray

With the benefits of 3D scanning sprays being well-established across industries, there’s no shortage of product developers and resellers. Here are some of the biggest players:

- AESUB – Boasting a complete range of products, including different color sprays, spray guns, and point markers, AESUB is an early leader in this growing field.

AESUB Blue is said to be a particularly good low-smell, fast-evaporating option for scanning small geometries, with AESUB White being great for capturing glossy, coated surfaces. - REFLECON – Another early leader, REFLECON, offers semi-permanent and vanishing sprays, in addition to a pen applicator, across its TARNISH and TOPTRACK product ranges.

TARNISH 11 & TARNISH 50 are available in aerosol or container form (for spray guns), boast a long shelf-life, and remain on objects for up to 3 hours and 8 hours respectively. TARNISH 90, on the other hand, requires washing or wiping off, but delivers high productivity and allows for overhead spraying, making it ideal for scanning underneath large builds. - Dentaco – As its name suggests, Dentaco sells intraoral scanning sprays designed for dental users. Like those mentioned above, the firm offers products free of the possibly carcinogenic titanium dioxide (TiO2) – while also leaving behind homogenous, easily visible blue coatings.

- Dentsply Sirona – In CEREC Optispray, Dentsply Sirona markets an alternative non-toxic spray for dental model 3D scans, which also yields ultra-accurate digital impressions.

- Helling – With its 3D anti-reflection spray, Helling has brought an extremely popular product to the 3D scanning market. Designed to mattify mirrored surfaces, the aerosol is used everywhere from dental to aviation and automotive, for capture, measuring, and non-destructive testing.

Alternatives to 3D scanning spray

A brief Google search will reveal that there are plenty of household products that can be used in place of 3D scanning spray. Foot spray, dry shampoo, talc, and fake snow are just some of the alternatives suggested by users on online message boards.

But there are plenty of reasons to stick with professional products. First of all, specially formulated sprays will definitely wear off, at set intervals. Safety is also worth considering here, as many household sprays like cleaning products include potentially harmful chemicals.

On the flipside, your application may not even need scanning spray. Submillimeter accuracy is now the standard in handheld 3D scanning. When struggling to capture a surface, you can always adjust your scanning setup, or choose to invest in other products like targets.

It all depends on your specific project. But as a rule of thumb, it can be said that 3D scanning sprays generally improve accuracy when digitizing dark, shiny, or reflective surfaces. So, for professionals seeking to achieve the best possible results, sprays are worth weighing up.