Until fairly recently, even the most ardent believer in additive manufacturing would say the idea of producing and selling 3D printed meat at any kind of scale was pretty far-fetched.

However, the technology behind the concept continues to come on leaps and bounds. While some have managed to rustle up experimental 3D printed salmon, steak, and chicken-esque edibles, others are even starting to bring products to market. But why has the 3D printing of meat begun to gain traction now? And does it actually taste like the real thing?

3D Printed meat: trends

One of the main factors driving the development of meat alternatives is the world’s growing number of vegans, vegetarians, and those trying to reduce their meat consumption. With so many more people being turned off by the thought of eating a once-alive animal, demand for a substitute that provides similar nutritional benefits has soared. Likewise, livestock farming is a huge global CO2 contributor, and it’s thought that reducing the practice could be key to fighting climate change.

According to the UN Food and Agriculture Organization (FAO), animal farming is not only negatively impacting the biodiversity of our environment, but it is insufficient to meet global food needs. Last year, as many as 349 million people faced acute food insecurity, 200 million more than had been the case pre-COVID-19, and with the global population set to hit 2 billion by 2030, this problem will only get worse.

With so many wondering where their next meal will come from, and in the face of a massive opportunity presented by the world’s rising vegan population, it’s unsurprising that 3D printed meat has begun turning heads. The big question is, will the technology ever become capable of scaling to the point that it can address this growing market?

Let’s take a look at how the 3D printing of meat works, and more importantly, how close they are to hitting the shelves of your local supermarket.

How does 3D printing meat work?

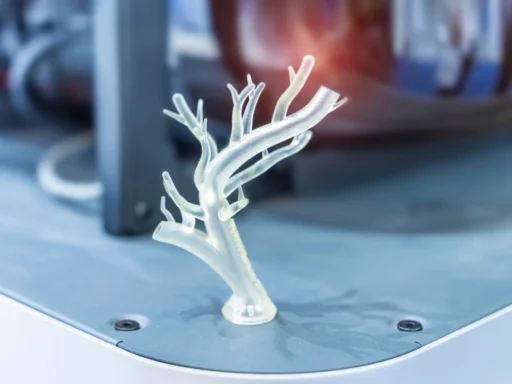

Also referred to as ‘3D bioprinting,’ the process of meat 3D printing is actually very similar to that of your average desktop 3D printer. Materials are deposited layer-by-layer to create structures in pre-designed shapes. Only instead of being printed from plastic, these are made of either animal stem cells, vegan-friendly ingredients like chickpeas and beetroot, or a mixture of the two, and designed to look like real meat products (rather than parts).

Sounds easy enough, right? Well, there are a few hurdles that need clearing before 3D printing meat is possible. First of all, product developers have to source their feedstock. For those using animal stem cells, these are often lab-cultured, differentiated into muscle and fats, and printed into shape. On the flipside, when it comes to rustling up 3D printed vegan meat, manufacturers tend to turn to common vegan-friendly ingredients like soy and coconut fat.

Fundamentally, all the technologies deployed to 3D print these faux meats involve the same layer-by-layer process, but while some use extrusion to carry it out, others have adopted more advanced sintering or material jetting techniques. Which one of these production processes is used (in tandem with a meat alternative’s ingredients), ultimately plays a huge part in their potential commercial viability.

That said, however they’re produced, and wherever you stand on the ethics of eating animal stem cells, 3D printed meats do come with inherent advantages over their conventional counterparts. As with regular additive manufacturing, meat 3D printing minimizes material wastage, meaning that there’s little to no edible food disposed of during production. While 3D printers are still power hungry, they can also be deployed on-site. This technically means faux meats can be made and cooked in homes or restaurants, to bypass CO2-intensive shipping.

| Meat 3D printing technologies | |

| – Extrusion – Mult-printhead | – Selective Laser Sintering (SLS) – Material jetting (inc. binder and inkjet 3D printing) |

Different types of 3D printed meat

So, that covers off the technical side of meat 3D printing, but how exactly is the technology being used in practice? Believe it or not, while they’ve not all made it to market yet, there’s already a smorgasbord of 3D printed dishes under development out there, so there’s bound to be at least one that can tickle your taste buds.

Earlier this year, Steakholder Foods and Umami Meats were awarded $1 million to develop an edible, 3D printed eel. Other fish food products in the making include Legendary Vish’s vegan-friendly 3D bioprinted salmon, and CellMEAT’s Dodko cultured shrimp.

If 3D printed seafood doesn’t sound appealing, how about an artificial steak? Over in Israel, MeaTech continues to hone in on the perfect recipe, and back in 2021, the firm revealed it had cultivated an entire 3.67oz steak at one of its labs. That year, Novameat also announced that it had set its sights on the mass-market, and the development of a 3D printed vegan meat made from plants rather than animal cells.

Composed of organic ingredients like rice, peas, and nutritious seaweed protein, it’s said that the company’s steaks can be shaped into filets using 3D printing, before being cooked to give them a realistic taste and texture. While Novameat’s technology is designed to create pork and beef replacements, the likes of MeaTech are also working on chicken-imitating products.

Rather than developing 3D printed chicken meat filets, the firm has come up with a way to produce artificial fats. MeaTech is already said to have begun producing these at a pilot plant, with the end-goal of bringing them to market as a less cruel, more eco-friendly alternative to regular meat garnishes, in the near future.

So can I buy 3D printed meat?

Despite the advances being made in lab-based settings, 3D printed fake meat products haven’t yet realized their mass-market potential. That said, they are making small inroads, with a number of restaurants in Germany, the Netherlands, and the UK reportedly starting to serve 3D printed steaks over the last couple of years.

Elsewhere, in the face of rising faux meat demand, some manufacturers have begun to scale their production capabilities. North Carolina-based meat cultivator Believer Meats unveiled plans for a 200,000 sq. ft. facility last year. Once built, the world’s largest factory of its kind will be able to churn out 10,000 metric tons of meat alternatives each year, a capacity that’s set to make it a leader in an emerging industry.

Given the clear environmental advantages to cultivating and 3D printing meat, you may be asking yourself why the technology hasn’t disrupted the traditional food market. Well, there are several drawbacks to current cell 3D printing food processes. One of the main issues is cost, as acquiring meat 3D printers can be prohibitively expensive, and scaling production is still tricky, meaning end-products tend to be pricey.

Another key question lingering over the meat 3D printing industry is regulation. Before 3D printed meats can start hitting the shelves, their developers need to prove they’re safe for mass consumption. Traditionally, the FDA doesn’t regulate meat products, but it was agreed in 2019 that an exception would be made for those made from cultured cells.

Since then, UPSIDE Foods has become the proud developer of the first lab-grown meat approved for human consumption. However, at time of writing, this is pending further review by the US Department of Agriculture, so it appears that 3D printed meats still have a few more regulatory hoops to jump through, before they can be considered genuine challengers to farmed meat products.

Salivating over 3D printing’s future

Overall, while the technology behind the 3D printing of meat still has several hurdles to overcome, its potential to disrupt the food industry is undeniable. Take the success of other (non-3D printing-related) meat culture specialists like Beyond Meat. The firm’s product has even managed to attract the attention of fast food juggernauts like McDonald’s, and it’s now responsible for the chain’s ‘McPlant’ burger.

With reports that KFC started trialing 3D printed chicken nuggets made from plants as recently as 2020, it appears that additive manufactured alternatives could soon be on their way. Mind you, there’s no guarantee that once meat 3D printing has been perfected that customers will take to them. After all, general vegan meat products hit the shelves of supermarkets some time ago, and they’ve still not unseated those made from real livestock.

In fact, data collected by the Good Food Institute (GFI) across 2021 showed that plant-based meat represented just 1.4% of the USA’s retail meat market. This despite growing demand for products like Plantcraft Pâté, a vegan-friendly meat alternative that launched across the Atlantic earlier that year.

As is so often the case in the food industry, appealing to the customers’ taste buds could therefore mean the difference between success and failure for meat 3D printing. Whether they’re appetizing is of course a matter of opinion, but on paper at least, the technology has all the potential of a greener meat-alternative production process.