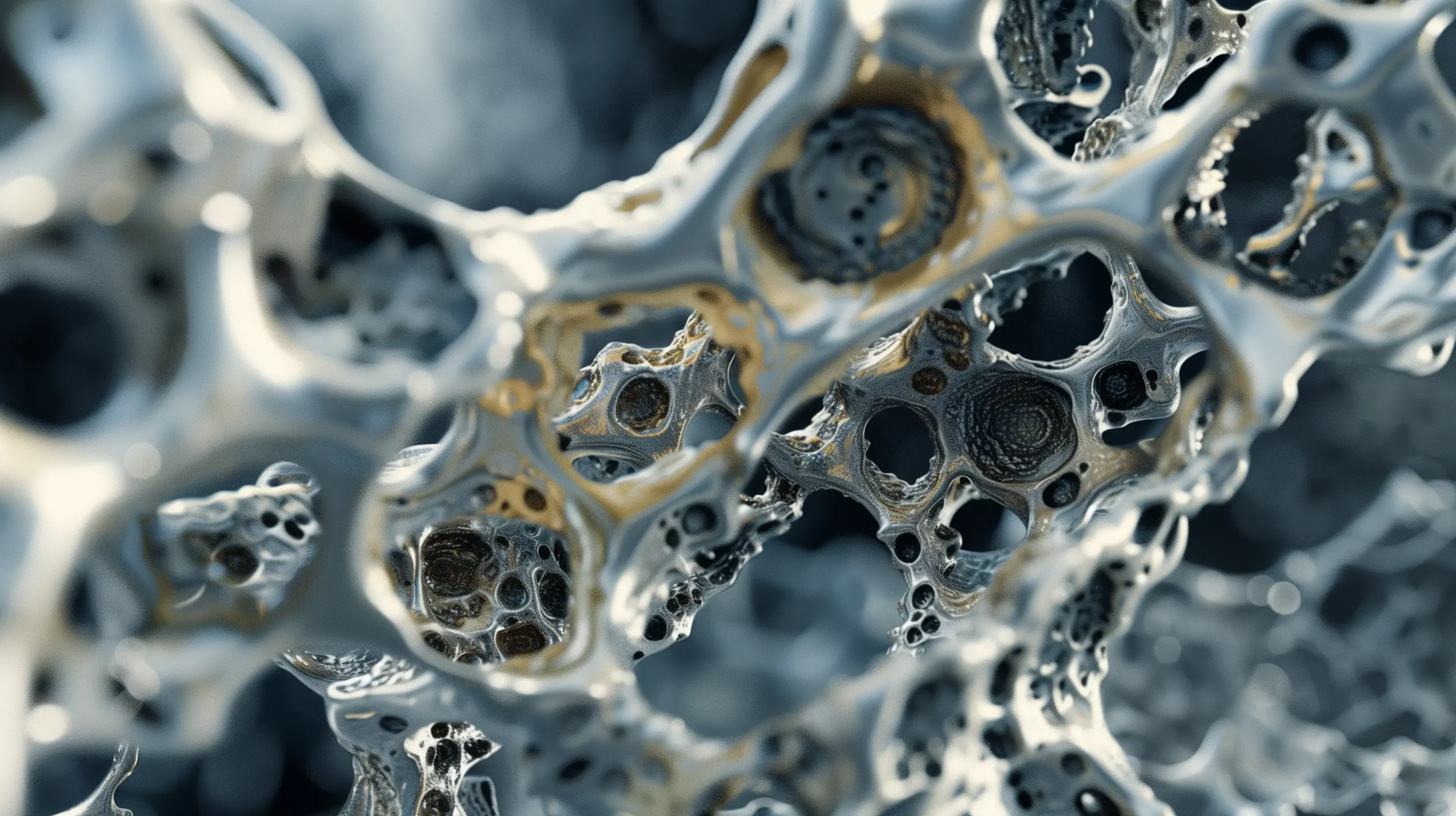

Researchers at RMIT University in Australia have developed a game-changing 3D-printed “metamaterial” with outstanding strength for its weight, which outshines natural materials and many existing manufacturing standards. Made from a common titanium alloy, this artificial material boasts a unique lattice design, making it twice stronger than the next most robust alloy of similar density, commonly used in aerospace applications. The implications of this innovation reach far and wide, across a range of industries, from medical implants to aircraft and rockets.

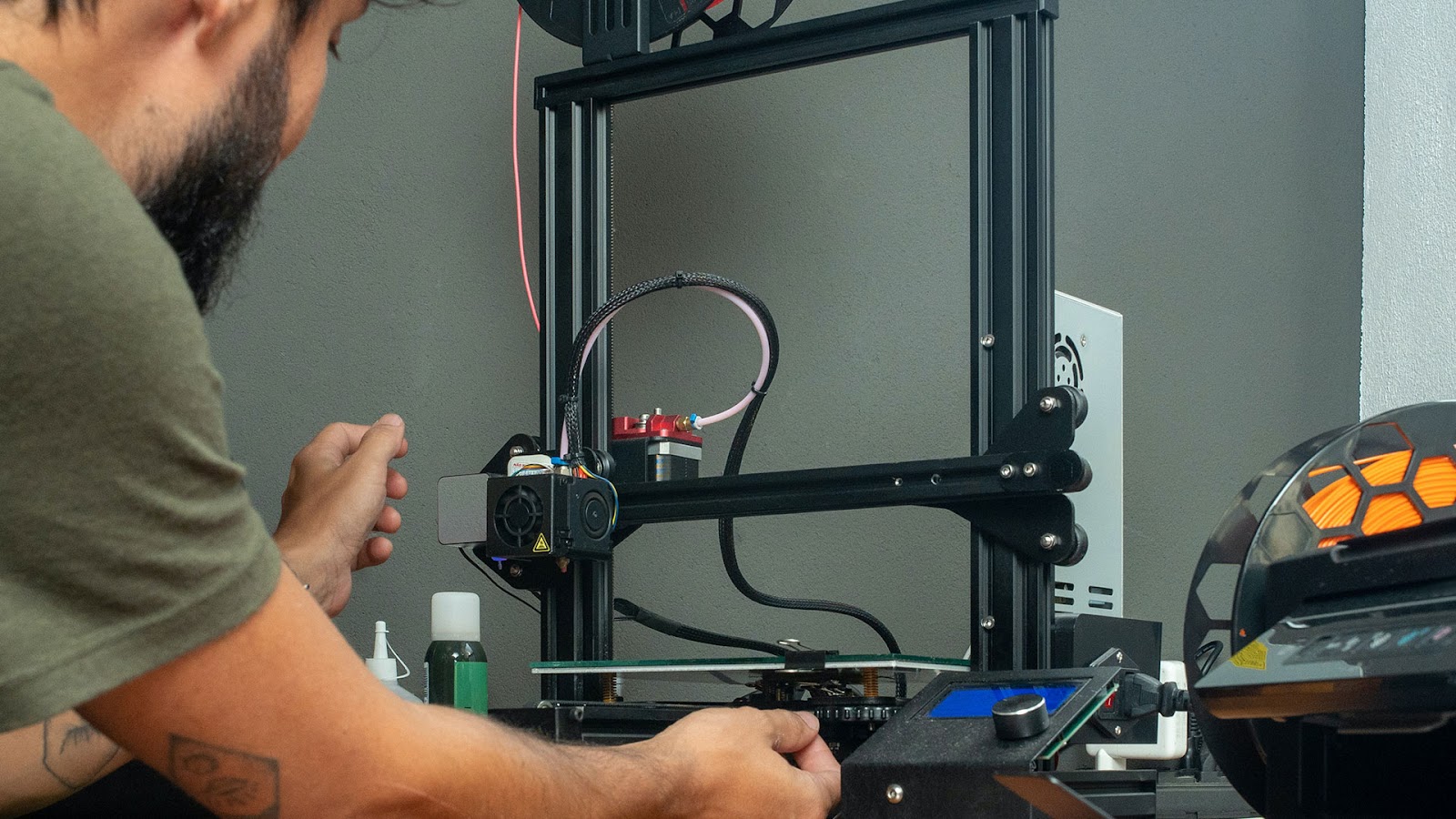

Inspired by the resilience of natural structures, especially hollow-stemmed plants like Victoria water lilies and corals such as organ-pipe coral, the researchers aimed to copy their strength and lightness. Previous attempts to recreate cellular structures from nature faced manufacturing and load stress challenges, but the team tackled these obstacles with metal 3D printing.

Distinguished Professor Ma Qian explained, “We designed a hollow tubular lattice structure with a thin band running inside it, showcasing strength and lightness never before seen together in nature. By merging two complementary lattice structures, we evenly distribute stress, eliminating typical weak points.” The breakthrough opens new doors for materials science, providing a bridge between strength and lightness we used to think was impossible. And – who knows? – with this innovative material, we might soon be crafting things so novel they make current inventions look like museum artifacts.