As 3D data capture is progressing, it’s increasingly branching into new areas. First there was underwater photogrammetry, then airborne UAV 3D scanning, now Fraunhofer IOF researchers have taken things a step further… with dog-mounted 3D scanning.

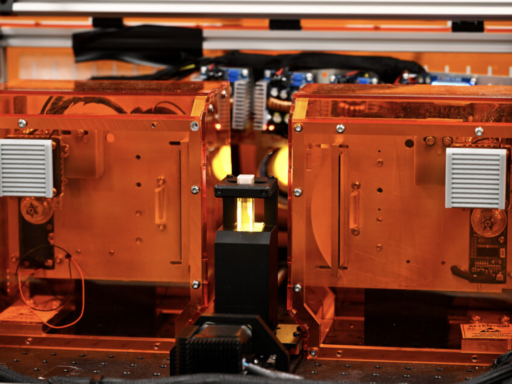

By attaching a 3D scanner to the head of Boston Dynamics’ robotic dog ‘Spot,’ they say it’s possible to make the technology more agile and flexible. In particular, they claim that Spot can achieve greater consistency, as it doesn’t get fatigued or make mistakes like humans do.

According to the team, such inaccuracies are a real issue on the factory floor, where the data capture workflow can sometimes be uncomfortable and inefficient for operators. Spot can also work in areas that people can’t – such as around guard rails in potentially hazardous environments – while digitizing highly complex objects from all angles.

However, Spot does still need human inputs to establish a reliable connection between itself and a 3D sensor, so human beings aren’t entirely absent from the process.

“Before the actual measuring process, speed, precise measuring location, and other important parameters are submitted by a human operator to Spot,” explained Dr. Andreas Breitbarth, Head of Image Processing and AI at Fraunhofer IOF. “[But] the robot dog can conduct scans the same way as a human being, without the need for them to be physically present.”

In future, the researchers reckon their unique solution to reducing scan lead times and variability will lead to faster, more dependable data capture with potential quality control applications.

Debuted at the Control 2024 trade show, this modified Spot is certainly an interesting 3D scanning innovation. But for now it’s probably best to keep it on a leash. At least until we know its true data capture capabilities!