polySpectra, widely acknowledged for its robust photopolymer resins, is set to launch its latest Cyclic Olefin Resin, COR Zero, on Kickstarter. This next-gen material is designed for manufacturing-grade resin 3D printing, allowing users to print and process components at home, in the office, or in any kind of workshop using affordable desktop equipment.

“It took us more than a decade to develop a COR formulation that was safe enough and inexpensive enough for individuals to use in their own workshop,” said polySpectra founder and CEO Raymond Weitekamp. The Kickstarter platform is optimal for reaching those eager to innovate. “The kind of person who would be most empowered by COR Zero is the kind of person who would launch a Kickstarter for their innovative physical product idea,” Weitekamp added.

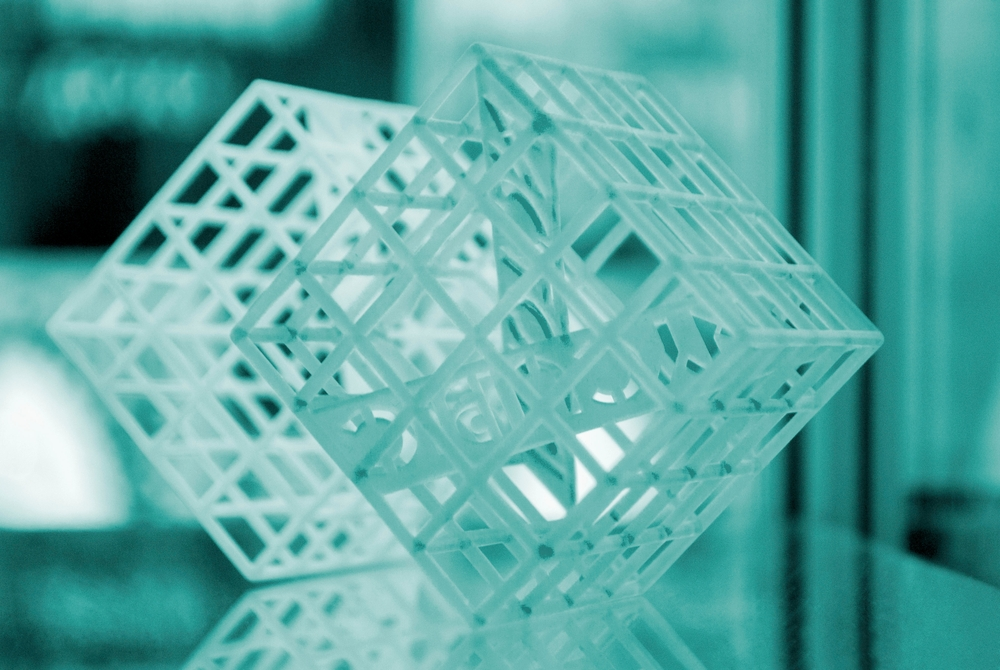

COR Zero marks polySpectra’s entry into the consumer market, enabling makers, designers, and engineers to bypass traditional injection molding. It aims to cut costs in a diverse range of applications, including mechanical components like gears and impellers, fluidic parts such as valves, electronic enclosures, and wearable products.

While many resin-based 3D printed parts struggle with brittleness and thermal stability, COR Zero is compatible with both industrial and desktop DLP/LCD printers. It demonstrates mind-blowing properties, such as an average tensile strength of 53 MPa and a glass transition temperature between 125° C and 145° C. With such impressive specs, we definitely join polySpectra in the hopes this powerful technology will drive innovation in hardware and durable goods.