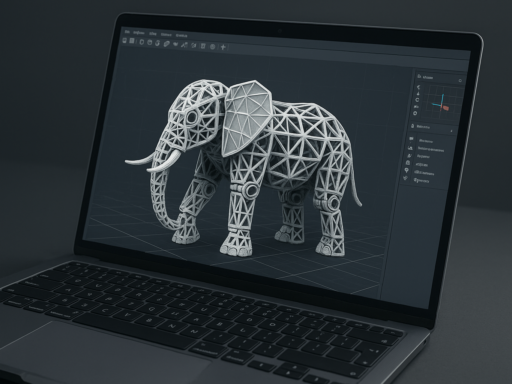

If you have a pile of empty plastic bottles lying around, Creative3DP might help you achieve next level recycling with their newest solution, PETFusion 2.0, fully funded on Kickstarter within three hours. The cutting-edge machine turns discarded PET bottles into top-quality 3D printing filament, making recycling easier, faster, and more accessible than ever before.

Building on the success of its predecessor, PETFusion, the newest iteration of the machine is an all-in-one, bottle-to-filament manufacturing unit. The device is both eco-friendly and cost-effective, bringing industrial-level capabilities in a compact portable shape. Game-changing new features include a motorized bottle cutter, dual hot-ends for simultaneous extrusion, and a filament welder that seamlessly joins shorter pieces into uninterrupted spools. For gorgeous hues, you can take advantage of enhanced ink-based colorizer and make your filament custom-colored.

PETFusion 2.0 is powered by a single motor that pulls the filament through the process and directly winds it onto a removable spool, simplifying and accelerating the entire workflow. Incredibly easy to assemble, the machine only requires affordable electronic components available across the globe. To ensure a seamless experience, Creative3DP provides a detailed package with the best sourcing links for all the components, encouraging users to purchase them locally.

“Our goal was to make recycling and 3D printing sustainable, affordable, and fun,” commented the Creative3DP team. It is exactly what is going to happen with the help of PETFusion 2.0 in its sleek, mostly 3D-printed design. Whether by makers, educators, or eco-enthusiasts, using the device will definitely support the recycling revolution.