Researchers at the University of New Mexico (UNM) have unveiled a unique bendable concrete with the potential to drive 3D printing adoption in the construction industry.

According to the project team, conventional concrete’s brittle nature and tendency to fracture under stress make it a risky choice of material. They also point out construction’s continuing reliance on wooden and steel frames – which can be pricey and dangerous to assemble.

Though several attempts have been made to use 3D printing to revolutionize the way infrastructure is built, the researchers argue that these don’t go far enough. With many still relying on supports, they say this limits the level of automation that can be achieved.

“If we talk about 3D printing or additive manufacturing in the fields of metals and plastics, it’s at a very advanced stage, but concrete printing is still developing,” said project researcher Muhammad Saeed Zafar.

“If we can successfully design ultra-high ductile materials without using conventional steel bars, we will solve the problem of the incompatibility of reinforcement with the 3D printing process.”

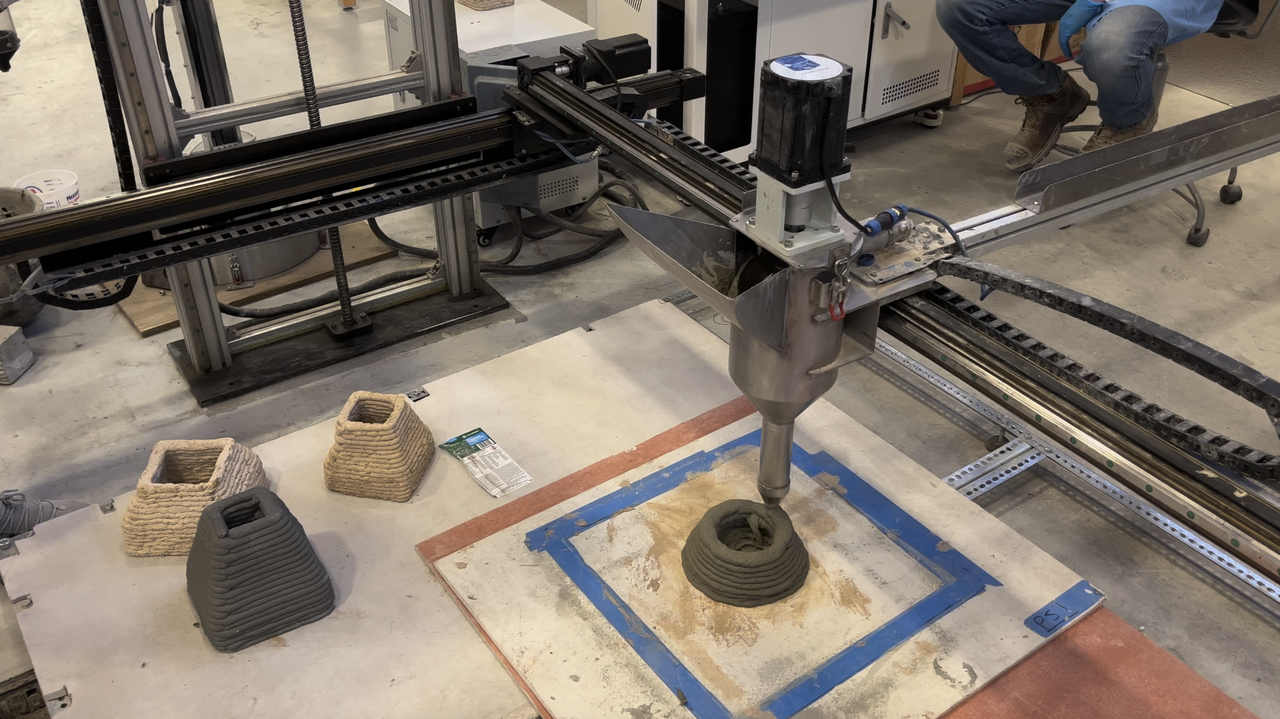

With their new material, that’s exactly what Zafar and his colleagues have done. Catchily named the “self-reinforced ultra-ductile cementitious material,” their formulation balances a high level of fiber for self-support, with the consistency required for 3D printing through a nozzle.

While developing their material, the researchers printed various small structures, prisms, and dog bones, then subjected them to tensile testing. Over numerous test cycles, which saw them experiment with everything from fly ash to silica fume, they identified the perfect formula.

Another of the project’s researchers, Maryam Hojati, attributes the success of their final material to the incorporation of “short polymeric fibers,” which hold it together under load. In future, she anticipates that the mixture – which has now successfully been patented – can be utilized at scale to minimize the need for construction reinforcement.

Given the recent struggles of construction 3D printing leaders like ICON and Mighty Buildings, it’s nice to see that innovation in this area is still alive and well.

If it’s going to be viewed as a scalable alternative to conventional construction, 3D printing still has a long way to go. But advances like those being honed at UNM only add to the technology’s credibility as a tool for building structures that will stand the test of time.