Automotive giant Ford has already 3D printed over 1,000 parts in preparation for its re-entry into Formula 1 with Oracle Red Bull Racing, according to a Top Gear report.

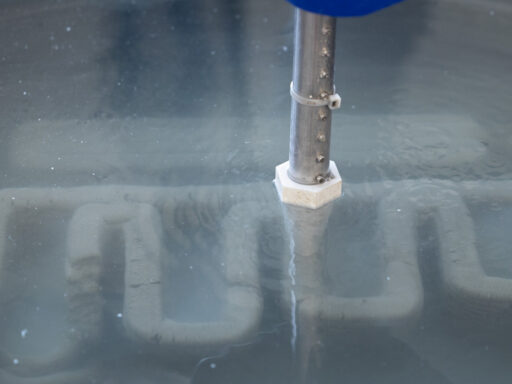

Ford, which is preparing for its first F1 season since 2004, is said to be using the technology to develop parts for batteries and cooling plates. Once ready, these test builds are reportedly fed into X-Ray and CT scanners, presumably to check if they meet desired tolerances.

With the 2026 season now just a year away, these R&D components sound like an exciting milestone on Ford’s return. Even if they’re not the very first F1 3D prints of their kind, they reflect Ford’s commitment to using all the technologies at its disposal to make sure it’s ready to go.

Re-entering Formula 1 at top speed

Ford may not have competed in F1 since its ill-fated Jaguar entry, but its engineers have still been hard at work developing parts for its other cars using advanced technologies. As such, the manufacturer hasn’t missed a step when it comes to 3D printing – it’s already an avid fan.

In 2022, Ford announced that it had begun automating the operation of Carbon 3D printers at its Advanced Manufacturing Center in Michigan using robotic arms. More recently, it was revealed that Formlabs SLA & SLS 3D printing was behind the testing of the new Ford Explorer.

Ford’s latest application of the technology is said to be in a similar role: inspection. Apparently, its motorsport division is already assessing the mechanical strength, hardness, and geometric compliance of prototypes, although accuracy and precision testing is done elsewhere.

“It’s not things like nuts and bolts and easy stuff,” explained Christian Hertrich, chief powertrain expert at Ford Performance Motorsports. “These are complex metal and polymer parts that get tested to extremes so they can withstand races that average 200 miles an hour.”

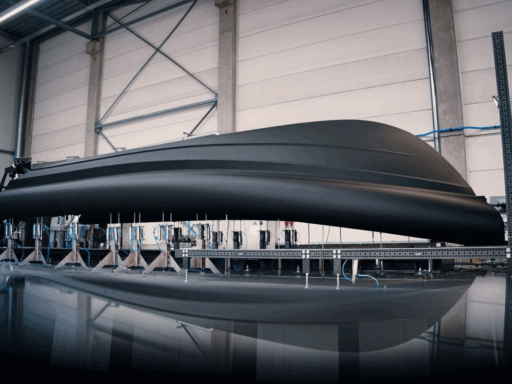

When it enters F1 in-full, Ford will effectively be in charge of engine development. This means the parts it makes for Red Bull need to demonstrate bulletproof reliability, if the team are to continue competing at the front of the field. Ideal for rapidly creating unique parts in relatively small quantities, 3D printing is the perfect technology for design, testing, and iteration here.

Life in the fast lane with 3D printing

In the high-octane world of F1, split seconds can mean the difference between first and last place, so precision is absolutely critical to on-track success. As such, Ford is far from the first to integrate the technology into its vehicle production workflow.

SLA has been a popular means of creating test parts since the 1990s and most of the field is understood to use it in one way or another. McLaren, for instance, has a long-running deal with Stratasys, not just for prototyping but the production of end-use F1 car parts.

Ford’s prototypes aren’t the first to be tested for Red Bull by a third-party either. As reported by 3D Mag, the team has also been working with Hexagon to analyze and reduce failure rates.

Clearly, F1’s development race remains as competitive as ever. Will Red Bull & Ford come out on top? In the near future, the stopwatch will give us the answer!