Parisian artist Raphaël Emine has unveiled a series of beautiful 3D printed ceramic structures, designed to serve as tiny hotels that boost biodiversity among insects and other wildlife.

Each of these Utopies Entomologiques (or Entomological Utopias) feature intricate tunnels, corridors, and balconies that appear ‘carved’ into the walls for nature to thrive in.

Emine has also applied this approach to the creation of highly complex 3D printed nests. Now at the center of research at Marseille’s Parc Maison Blanche, these designs could help uncover how colors and shapes attract different species, so they can be encouraged to thrive.

Drawing inspiration from nature

Emine’s ‘insect hotel’ designs aren’t just built for nature, they’re inspired by it. Whether it be honeycomb cells, worm and spider webs, or mineral formations, the designer has very much chosen to build these tiny homes in the image of their natural dwellings.

Designed for prolonged outdoor usage, these tiny homes are also said to “metamorphose to the rhythm of the seasons,” so they can “actively support” environmental conservation.

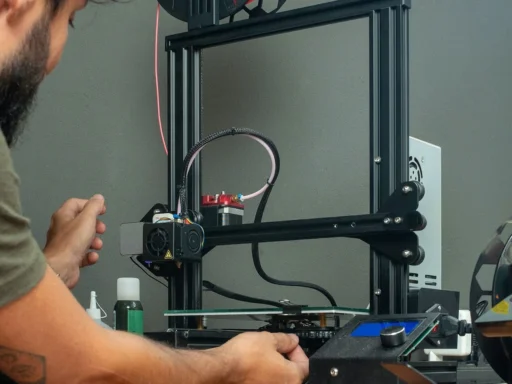

Like the artist’s nests, which have been planted in weevil-ravaged palm trees to encourage new life to blossom, his insect hotels were created using a mix of traditional technologies and WASP 3D printing. Doing so has allowed Emine to bring his vision to life by digitally carving incredibly complex designs from clay in a way that wouldn’t previously have been possible.

According to WASP, “merging traditional clay modeling techniques with contemporary technologies like 3D printing… also captivates human viewers,” while showcasing its machinery’s “versatility and potential for innovative applications.”

Eco-friendly 3D printing at WASP

At this year’s Formnext, WASP unveiled numerous next-generation sustainable 3D printing technologies, which further underlined its commitment to green manufacturing.

During the show, the company introduced an XXL extruder and Power WASP 42 HDP for larger, angled 3D prints, as well as a RIGENERA print pellet recycling system. This offering, alongside WASP’s existing Power, Delta, and Crane machinery should allow WASP customers to expand their horizons and get even more creative with clay and recycled polymer 3D printing.

From bio-friendly building projects like its TECLA habitat, to custom hull designs for racing boats, its technologies seem to know no bounds. It’ll be exciting to see where they’re used next!