Soft, flexible actuators – a breakthrough in artificial muscle technology – promise a whole new era for robotics, medicine, and beyond. Scientists at Empa’s Laboratory for Functional Polymers have developed a method to 3D print soft and elastic artificial muscles that can contract and relax like real muscle tissue, potentially keeping up with their biological counterparts. According to ScienceDaily, when fully developed, this innovation could be used in advanced prosthetics, exoskeletons, and even bio-inspired robots that move with unprecedented agility.

Detailed in Advanced Materials, the project focuses on silicone-based components that convert electrical impulses into movement, called dielectric elastic actuators. DEAs consist of conductive electrode materials and non-conductive dielectrics, layered together in an interlocking structure. “It’s a bit like interlacing your fingers,” Empa researcher Patrick Danner explained. When voltage is applied, the actuator contracts; when switched off, it relaxes. Actuators can already be used in any situation where movement starts with a push of a button, but these mechanical components are not capable of fully replacing human muscles – not yet.

3D printing such structures is a major technical challenge: the materials must remain separate yet bond seamlessly, maintaining their shape while being kept as soft as possible. “These properties are often in direct contradiction,” said Danner. “If you optimize one of them, three others change… usually for the worse.“

Having partnered with ETH Zurich, Patrick Danner and Dorina Opris, head of the Functional Polymeric Materials research group, have come up with a solution to overcome these challenges. Using two specialized inks and a custom-designed printing nozzle developed by ETH researchers Tazio Pleij and Jan Vermant, the team has successfully fabricated soft actuators that could take virtual reality gloves, robotics, and medical implants to an unprecedented level. This collaboration is part of the large-scale project Manufhaptics, a part of the ETH Domain’s strategic area Advanced Manufacturing.

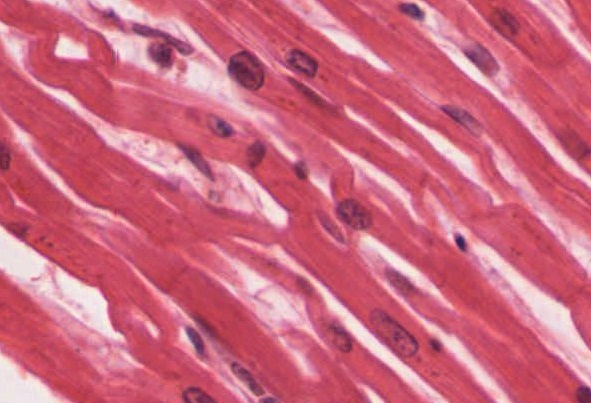

One of the most ambitious visions of the scientists is 3D printing artificial heart tissue. “If we manage to make them just a little thinner, we can get pretty close to how real muscle fibers work,” said Opris.

While still in its early stages, this project moves us one step closer to bioengineered muscle tissue, if not a fully 3D-printed heart.