Los Angeles prop studio owner, Frank Ippolito, is revolutionizing film prop creation through the integration of 3D printing. His studio, Thingergy, uses this cutting-edge technology to efficiently manufacture props, such as Star Wars lightsabers and Mandalorian armor, which are not only visually stunning but also practical.

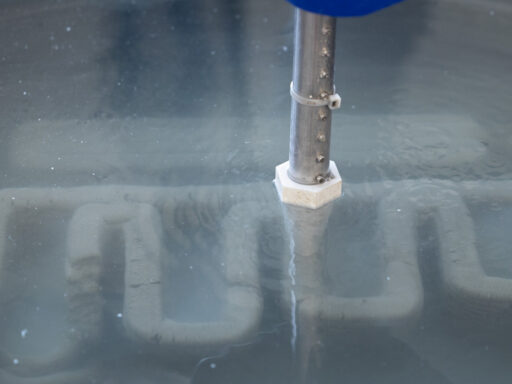

3D printing, a technique of layering materials to shape a product, deviates from the traditional carving or molding processes. The film industry has been quick to embrace this technology, recognizing its potential for producing intricate, customizable props at a rapid pace.

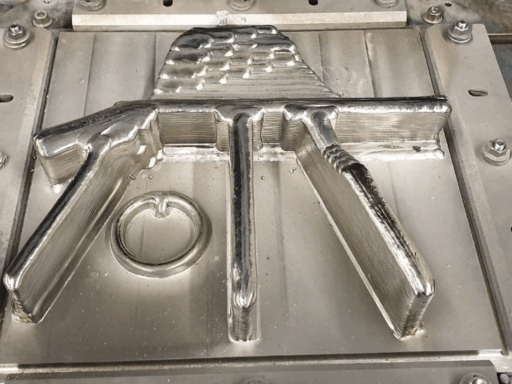

Thingergy’s journey with 3D printing began around ten years ago for prototyping purposes. Early models, however, lacked durability, breaking easily during filming. The game-changer was the Mark Two. Priced at $20,000 and created by Markforged, this compact printer crafts components using a fusion of nylon and continuous carbon fiber, rivaling the strength of aluminum.

This innovation bridges the divide between consumer and industrial-grade 3D printers. Firms like Ultimaker and Raise3D are joining the trend, developing desktop solutions that merge engineering-grade materials with dependable outcomes. Tripp Burd from Markforged highlights the printer’s versatility, pointing to unconventional uses in areas like animatronics and footwear.

The film industry’s growing affinity for 3D printing mirrors its rising prominence across sectors. As the capabilities of desktop 3D printing expand, it emerges as a practical, universally relevant manufacturing solution. Reflecting on this evolution, Ippolito comments that what once seemed magical and mysterious about 3D printers has transitioned into a valuable tool enhancing professional work.

In embracing 3D printing, studios like Thingergy are shaping the future of prop creation, ushering in an era of amplified creativity and efficiency. The path forward involves identifying the most fitting 3D printing technology and equipment to align with traditional practices, leveraging this potent resource to conjure tomorrow’s cinematic wonders.