A groundbreaking 3D printing technology capable of precise light control for structural coloration has been developed by Dr. JaeyeonPyo’s team at the Korea Electrotechnology Research Institute (KERI). The world-first technology, suitable for transparent displays and AR devices, replicates the physical phenomena behind a chameleon’s changing skin color or a peacock’s vibrant feather hues.

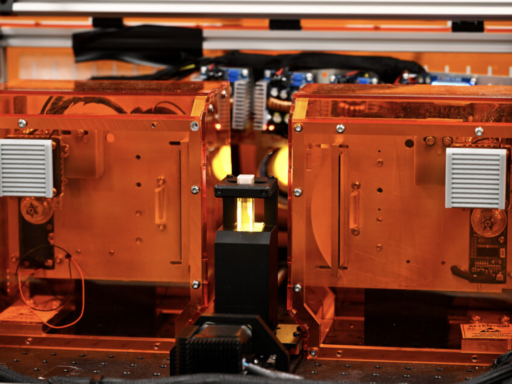

KERI’s breakthrough involves realizing a “diffraction grating” capable of precisely controlling structural color through nanoscale 3D printing technology. A diffraction grating is a device with a regularly arranged microstructure for controlling light diffraction. When illuminated, the light reflects in different paths depending on the wavelength, creating a specific structural color or spectrum. In essence, it’s a 3D printing technology allowing precise light control for vivid coloration without dyes.

The demonstrated diffraction grating is expected to find applications in various advanced display technologies. Given its transparency, it can be utilized in future transparent displays like smart windows, mirrors, and heads-up automotive displays.

Additionally, the technology has applications in AR devices already using diffraction gratings as a crucial component. Diffraction gratings can be designed to emit different colors based on deformation, making the technology useful in mechanical engineering and biomedical applications requiring deformation detection, and it can be applied in various optical physics research.