Desktop 3D printer manufacturer Bambu Lab has launched a system that’s designed to set a new standard in precision and performance for makers and engineers everywhere.

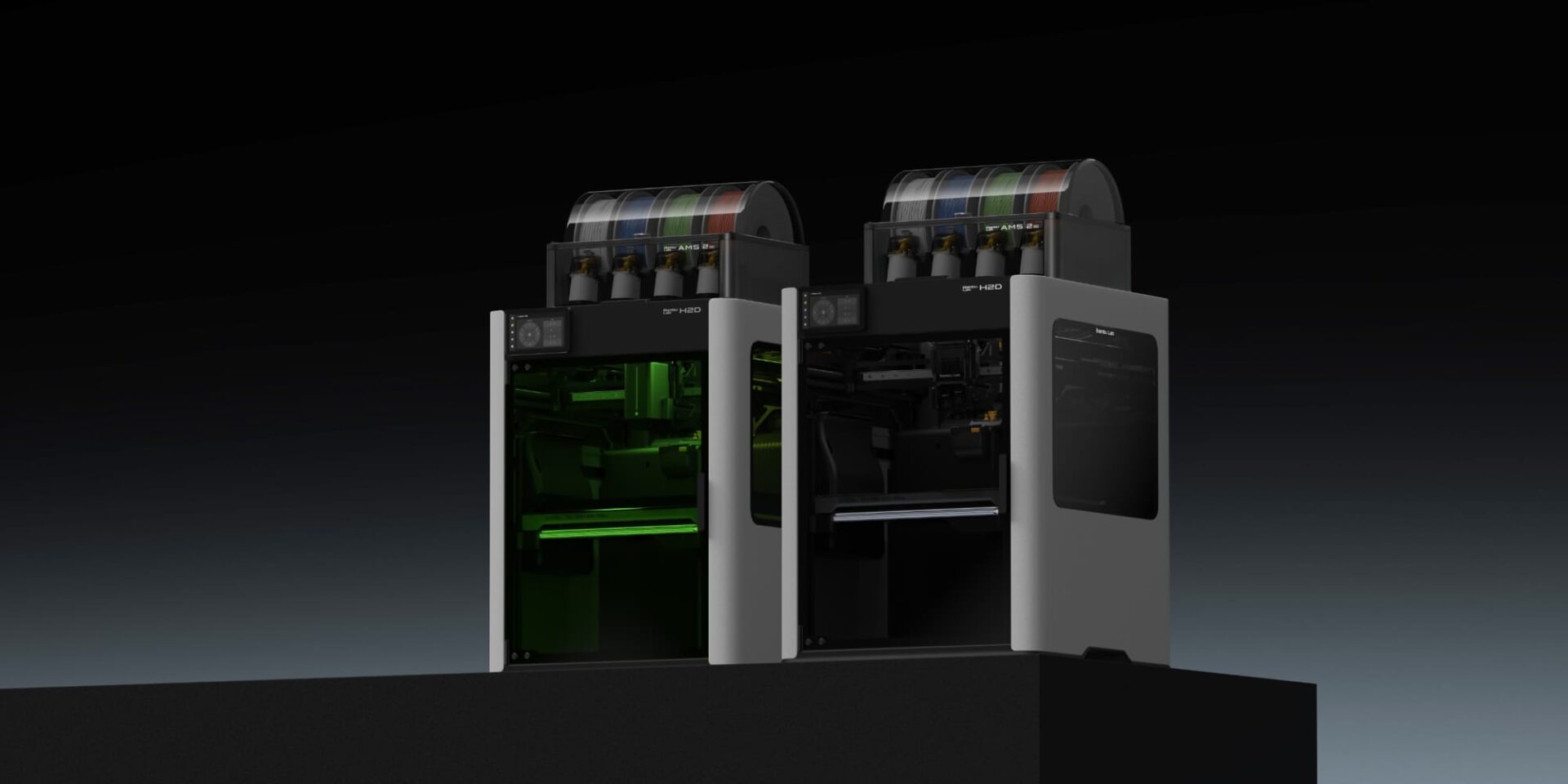

The Bambu Lab H2D integrates 3D printing, laser engraving, and precision cutting into a single unit, making it an end-to-end manufacturing solution. According to the company, its new flagship machine is an “entirely new category of product” because it doesn’t compromise on any of its core functions, instead delivering “exceptional performance” across the board.

“The H2D represents the culmination of our vision to fundamentally transform how designers, engineers, and makers approach personal manufacturing,” explains Bambu Lab CEO Dr. Tao. “We’ve built the H2D with the goal to excel at every capability it offers, eliminating the traditional ‘jack of all trades, master of none’ compromise that has plagued this product category.”

Introducing the all-new Bambu Lab H2D

On the 3D printing side of things, the H2D’s headline addition is the integration of a dual-nozzle system. This makes it possible to print multi-material parts from different colored filaments. The machine also features an enclosed chamber that heats up to 65°C, allowing for the printing of engineering-grade materials, including those reinforced by carbon or glass fiber.

Alongside a larger 325 x 320 x 325 mm³ build volume, the H2D includes numerous innovations that make it a significant step up on its predecessors. For instance, the device ships with an AI-powered nozzle camera that tracks material deviations. It also features filament drying, heating, and flow monitoring, in addition to a motion accuracy-boosting encoder.

Impressively, the maxed out version of the H2D comes with laser engraving and cutting capabilities too. Featuring an air assist pump and vision alignment system, the machine enables users to engrave onto complex curved surfaces, 3D printed or otherwise. Similarly, its digital cutting and pen drawing tools allow for the precise creation of vinyl cuts, stickers, or drawings.

In its marketing materials for the H2D, Bambu Lab boasts of the possibilities unlocked by the 3D printer’s broad feature set. With its dual-nozzle, it’s possible to make something like a bike helmet in a single piece, which combines a soft inner material with a harder outer shell. Its humidity control, meanwhile, makes it ideal for TPU 3D printing items like insoles.

When will the Bambu Lab H2D be available?

Makers will be relieved to hear that Bambu Lab has not raised the price to reflect the improved performance specs of its new 3D printer. Starting from $1,899, the machine remains very much in the consumer/prosumer price category, but it depends which version you choose to buy.

The standard edition, complete with a higher accuracy, speed, and build volume, will be available at the base price. Adding the AMS 2 Pro material management system raises the price to $2,199, while integrating a 10W or 40W laser will take this to $2,799 and $3,499, respectively.

All the combo editions are available for pre-order today, with shipping of the laser-mounted systems beginning at the end of April. The standard H2D 3D printer will ship in June 2025.

This is an exciting development for one of 3D printing’s hottest brands. Will you be picking up the H2D? If you’re looking for alternatives, check out our best 3D printer guide here.