Now, if you only imagined glam and glow thinking of Swarovski, get ready to be surprised: the brand renowned for its high-quality crystal products has teamed up with Xolo to explore advanced 3D printing techniques for crystal glass. This groundbreaking partnership is supported by Concept Laser founders’ HZG Group and guided by Professor Paolo Colombo’s team from the University of Padova, promising to enhance crystal manufacturing precision and speed with Xolo’s proprietary Xolography technology.

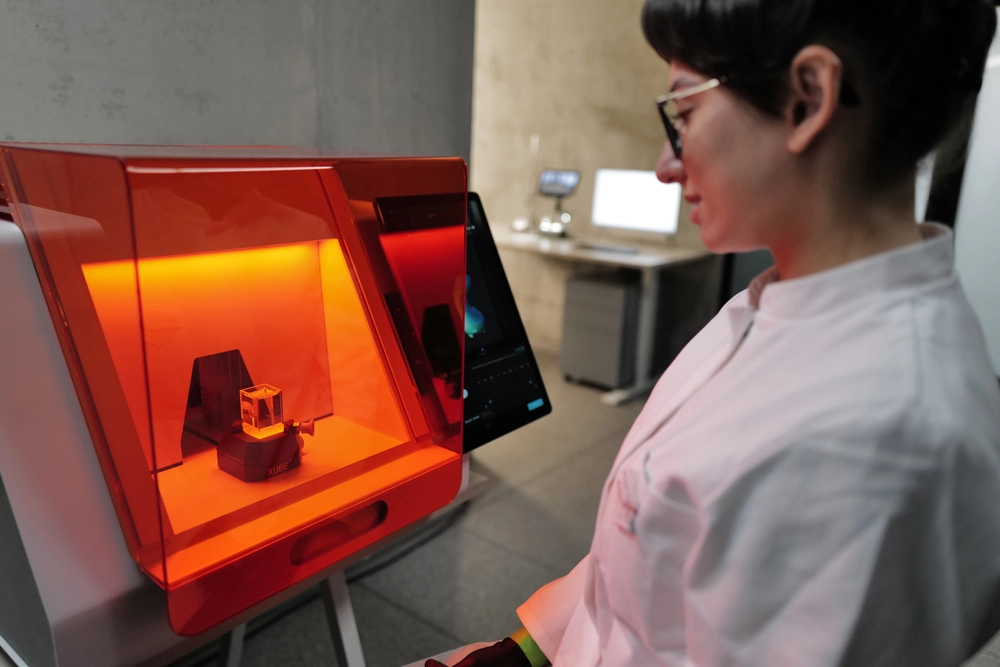

Swarovski is not new to the blend of craftsmanship and high tech, having honed their art of crystal cutting and design since 1895. Collaborating with Berlin-based professionals in 3D printing for glass creates a new definition of crystal. Xolo’s latest Xube² Volumetric Printing system boasts a dual-wavelength light projection in resin-filled cuvettes, creating highly detailed structures with rapid precision. Originally designed for biocompatible materials and tech applications, Xolography is now used to produce crystal components with a morning-dew transparency for Swarovski’s products.

Xolo CEO Dirk Radzinski said, “Partnering with a prestigious company like Swarovski offers an incredible opportunity to demonstrate the capabilities of Xolography in a new and innovative field.”

Known across the globe for its crystal artistry, Swarovski aims to combine its historical craftsmanship with Xolo’s unique technology to shift industry standards.

Early outcomes from this collaboration can potentially set new benchmarks in glass and crystal manufacturing, so it’s time for the 3D printing technology to sparkle and shine – quite literally.