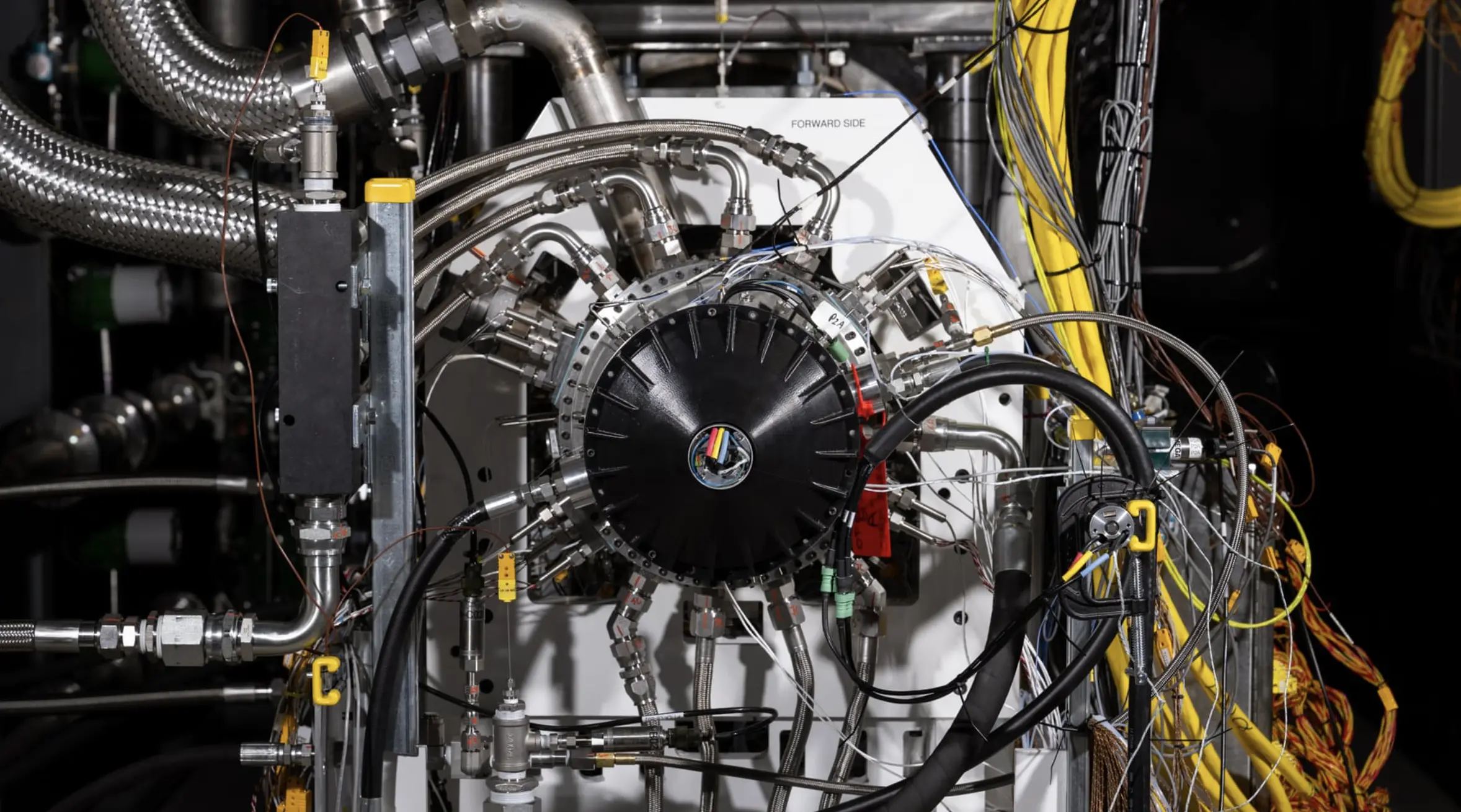

Beehive Industries, the pioneering jet propulsion company using additive manufacturing technology, has announced the successful completion of the first fire tests for its innovative 3D-printed engine demonstrator.

Designed specifically for unmanned aerial defense vehicles like cruise missiles, collaborative combat aircraft, and reconnaissance drones, the engine boasts remarkable efficiency and versatility. With a thrust capacity ranging from 250 to 1,000 lbf, it sets the stage for a new era in engine technology, showcasing 90% part consolidation and a price approximately twice lower that of traditionally developed engines.

Beehive CEO, Mohammad Ehteshami, expressed his excitement, saying, “This is a huge milestone for Beehive Industries, as well as our country. This program demonstrates the immense potential of additive manufacturing for defense applications, and I believe we’ve only just begun to tap into its possibilities.”

The achievement of the first fire test is a significant leap forward in the engine’s development, traditionally a long process in the industry. However, Beehive accomplished the feat in just 16 months, marking a new standard for efficiency in aerospace manufacturing.

Beehive’s success is an indicator of great advancements in defense technology, and we see why: the transformative potential of additive manufacturing in the entire aerospace sector is somewhat reassuring in times of geopolitical turmoil.