Research teams from MIT and Delft University of Technology collaborated to create a pioneering 3D printing technique called speed-modulated ironing, aimed to make customized objects more efficiently and with minimal waste. The method allows for the rigid control of color, shade, and texture with the help of a single heat-responsive material.

Conventional multi-material 3D printing can be arduous and wasteful, as it requires multiple nozzles and inevitably results in discarding the unused materials. In contrast, the speed-modulated ironing technique involves using a dual-nozzle printer, where the first nozzle deposits heat-responsive filament, and the second nozzle applies heat to activate specific material responses, such as changes in opacity or texture.

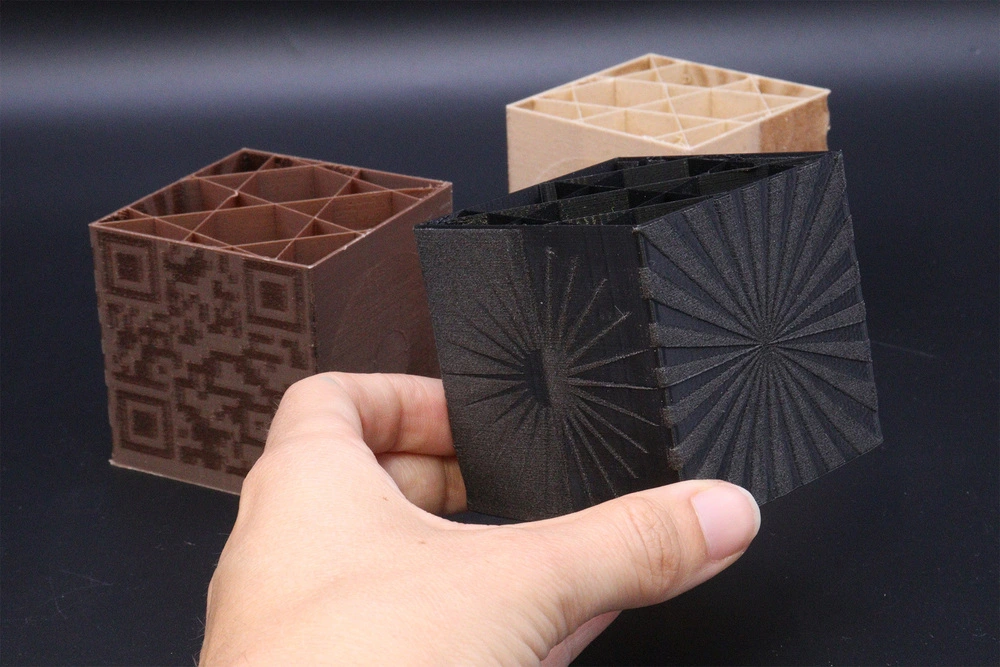

By modulating the speed of the second nozzle, researchers can fine-tune the printed object’s characteristics with no need for any additional hardware modifications. “Today, we have desktop printers that use a smart combination of a few inks to generate a range of shades and textures. We want to do the same with a 3D printer,” says Mustafa Doğa Doğan, co-author of the study.

The team developed an intuitive interface to simplify their scientific process by automatically turning 3D model pixels into machine instructions for a dual-nozzle printer, controlling the printing and ironing speeds. After testing their method with three heat-responsive filaments and varying ironing speeds, they were able to successfully produce objects such as partially translucent water bottles or a bike handle with different roughness to enhance grip.

In the future, the team plans to experiment with more thermally responsive materials, including plastics. They also would like to explore how speed-modulated ironing can be used to modify the mechanical and acoustic properties of certain materials. The initiative emphasizes that the new method can enhance countless 3D printing workflows, especially those for customization in manufacturing. The findings will soon be presented at the ACM Symposium on User Interface Software and Technology.

It’s very effortless to find out any topic on web as compared to books, as I found this post at this site.

Wonderful goods from you, man. I’ve keep in mind your

stuff prior to and you are simply too great. I actually like what you’ve got here, really

like what you are saying and the way by which you say it.

You are making it enjoyable and you still care for to keep it smart.

I cant wait to learn far more from you. That is actually a

wonderful site.

Great post.