Imagine LEGO-like bricks made of glass that can be used in sustainable construction, reconfigured, and repurposed many times over. This is exactly what a team of MIT engineers had in mind when developing innovative 3D-printable glass masonry. The interlocking bricks they created were inspired by the concept of circular construction, aiming to reuse the building’s materials as much as possible, which reduces environmental impact by cutting down on greenhouse gas emissions and minimizing the need for new resources.

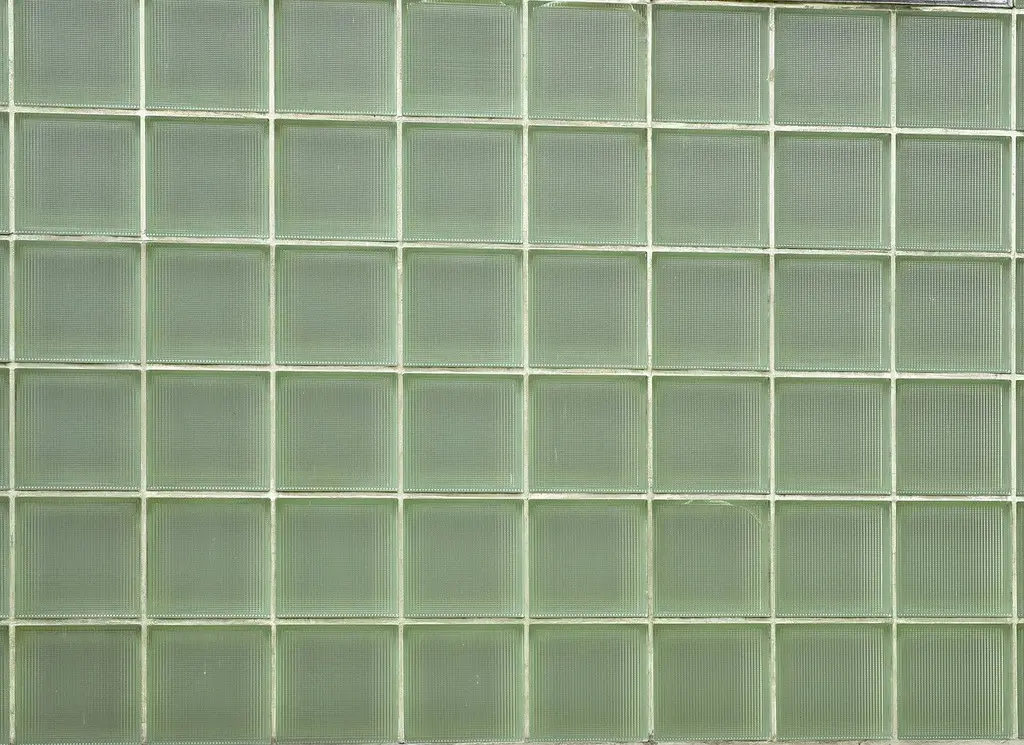

With the help of a custom 3D glass printing technology from MIT spinoff Evenline, the team crafted sturdy, multilayered glass bricks that can easily interlock and be assembled and disassembled when needed. When the researchers conducted mechanical tests, these bricks were able to withstand the pressure comparable to their concrete counterparts, proving impressive structural durability. To show the project’s potential, the engineers built a wall using their invention, demonstrating how recyclable bricks can form facades and internal walls.

“Glass is a highly recyclable material,” said Kaitlyn Becker, assistant professor of mechanical engineering at MIT. “We’re taking glass and turning it into masonry that, at the end of a structure’s life, can be disassembled and reassembled into a new structure, or can be stuck back into the printer and turned into a completely different shape. All this builds into our idea of a sustainable, circular building material.”

Michael Stern, founder of Evenline, added: “We’re pushing the limits of what’s been done in architecture with glass as a structural material.”

The study by Becker, Stern, and their team appeared in the journal Glass Structures and Engineering, and researchers plan to scale up their design in the future, hoping to construct larger structures like pavilions that can be reconfigured into different designs later on. With their sturdy yet eco-friendly material, we will probably see bigger, self-supporting glass structures very soon!