The (NIST), collaborating with Sweden’s KTH Royal Institute of Technology and other partners, has achieved a pivotal breakthrough in metal 3D printing. They have unveiled a method to predict and control metal 3D printed parts’ attributes, potentially standardizing and ensuring reliable manufacturing.

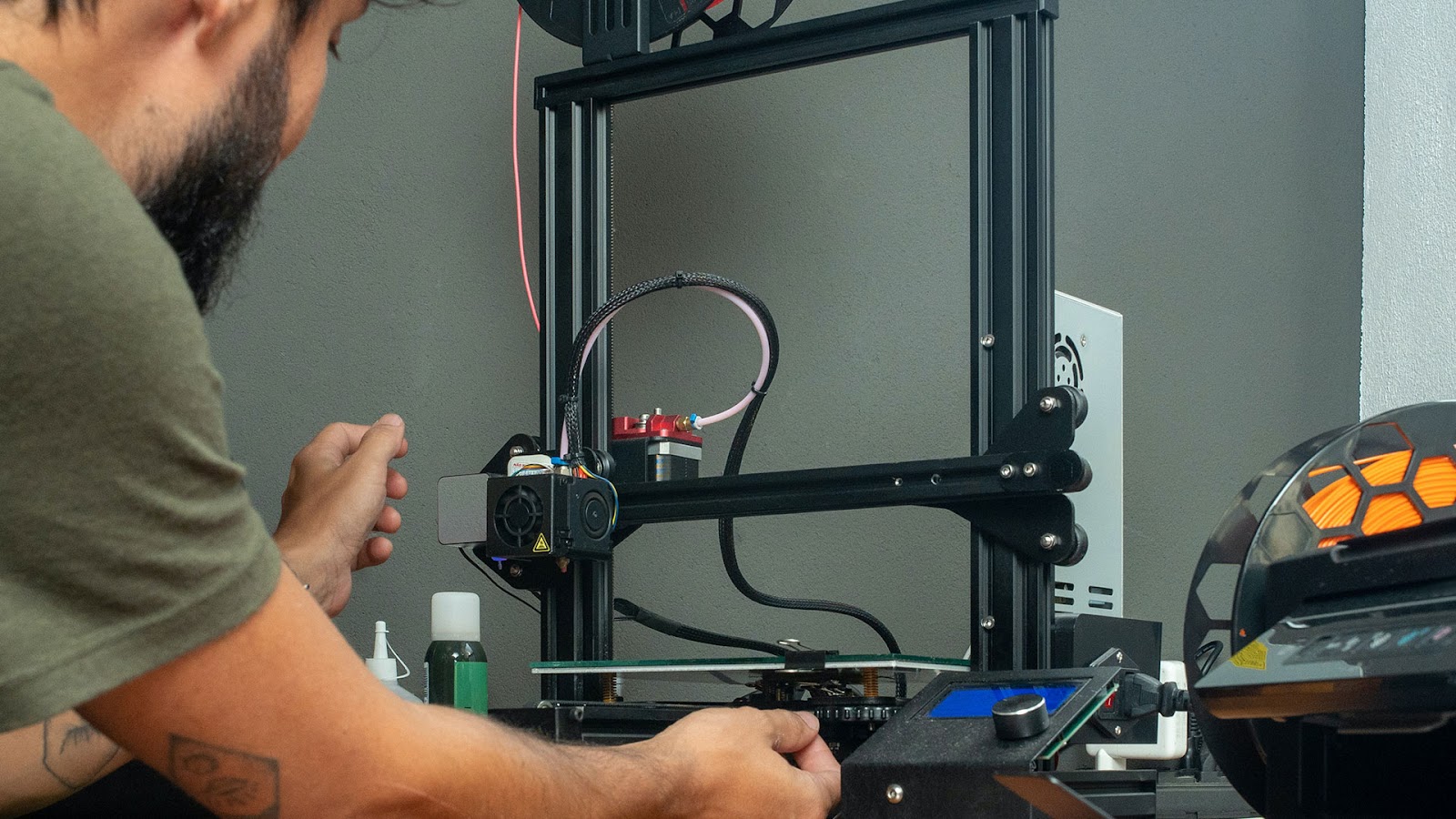

A primary hurdle in metal additive manufacturing is the limited insight into material behavior during printing. The absence of tools to monitor metals’ internal structures as they transition between molten and solid states during the process has hindered metal 3D printing’s extensive adoption.

Following the Biden Administration’s AM Forward Initiative, NIST allocated around $3.7 million in grants last year to address challenges in metal additive manufacturing. These projects centered on material properties’ comprehension for AM quality control and understanding the implications of AM for security-essential applications across industries.

NIST’s innovation revolves around discerning the melting and cooling speeds of metal during printing and their impact on the material’s crystalline structure. Researchers tapped into particle accelerators at Argonne National Laboratory’s Advanced Photon Source and the Paul Scherrer Institute’s Swiss Light Source. These accelerators emitted potent X-rays to snapshot processes at incredibly high temperatures. Utilizing high-speed X-ray diffraction, the team discerned the crystalline structures emerging within 3D printed steel.

NIST physicist Fan Zhang noted the significance of controlling microstructures during initial printing stages to achieve the desired crystals, influencing the performance of additively manufactured components. Zhang emphasized, “When we have data, we can validate models, and that can expedite the wider implementation of additive manufacturing for industry.”

This groundbreaking insight, providing unparalleled control over metal 3D printing processes, may catalyze consistent, dependable manufacturing, enhancing metal 3D printing’s allure for expansive industrial pursuits.