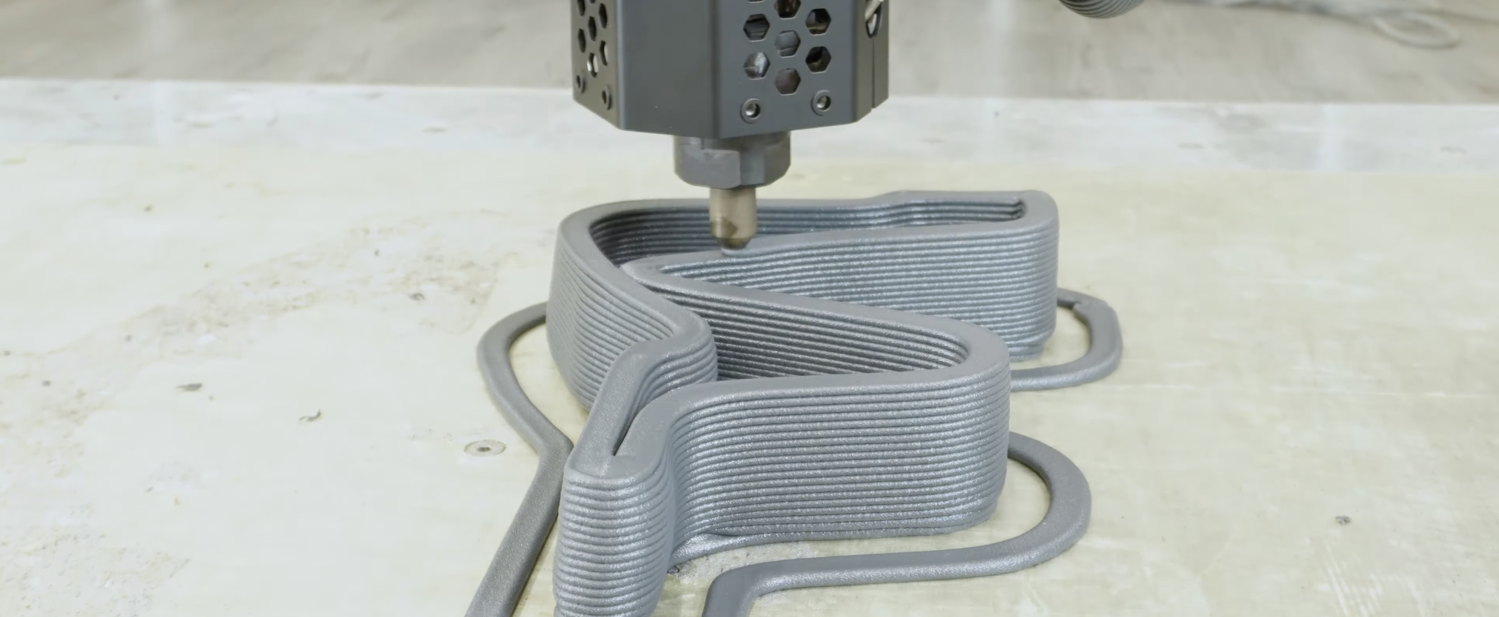

UK-based tech Rapid Fusion has collaborated with Italian start-up Nanoo to revolutionize concrete mould production using additive manufacturing. Leveraging its ZEUS 3D robotic system, Rapid Fusion created intricate moulds for table legs for an Italian furniture manufacturer in just days, less than half the time required by conventional methods.

By combining 3D printing with CNC milling and recycled PET-G materials, the partnership provided high-precision results, cut labor costs, and boosted sustainability.

“We have proven with our partners at Nanoo that large-format robotic 3D printing offers a faster, more sustainable, and cost-effective solution to the challenges faced by traditional concrete mould production,” said Martin Wood, director of sales at Rapid Fusion.

The landmark project turned out to be a success story to demonstrate the feasibility of using advanced cementitious materials, such as ultra-high-performance concrete (UHPC) with PET-G moulds. The case illustrated to the construction sector how 3D printing can be beneficial for bespoke moulds commonly used in massive projects, to create free form facade elements, intricate concrete structures and furniture components designed by world-leading architects and designers.

Initial tests confirmed high accuracy and production efficiency, predicting that moulds could be reused over 100 times without maintenance. The partnership also promises environmental benefits, slashing waste compared to traditional composite moulds.

“3D printing uses recycled materials and can be reused once the mould is done with. That’s a massive sustainable benefit for construction,” Wood explained.

The partnership expands Rapid Fusion’s presence in the European construction market, highlighted by Nanoo’s acquisition of the ZEUS robotic system. In addition, it serves as a great example of the benefits of additive manufacturing for bespoke architectural designs.