Over the last week, some of the biggest names in 3D printing have gathered in Detroit to showcase their latest innovations at RAPID + TCT.

After hours of keynote speeches, training courses, and showcases, the dust has finally settled, and we can finally gather ourselves for a launch review. From application-unlocking materials to 3D printers – both desktop and industrial – the event was jam-packed with new technologies.

Without further ado, let’s run through the biggest headlines from the show. If you couldn’t make it to Rapid + TCT in-person, this breakdown’s for you!

Big players make a splash at RAPID + TCT

Let’s start with the latest from FDM inventor Stratasys. At this year’s RAPID + TCT, the US-Israeli 3D printer manufacturer launched the Neo800+, a stereolithography (SLA) system designed for making large parts accurately, repeatedly, and with ultra-high fidelity.

According to Stratasys, the machine features an enhanced laser and optics system. This not only allows it to process high-energy materials, it significantly improves print speed. In-house estimates have clocked the 3D printer’s time-to-part speed boost at about 39%. These benefits only increase when it comes to making parts like tooling molds. Ultimately, the company says its latest unit is geared towards demanding industries like aerospace and automotive.

At the show, Stratasys also introduced the ToughOne material. Formulated for use with the manufacturer’s PolyJet machines, ToughOne combines 3D printing precision and functional strength to allow for the creation of representative prototypes and end-use parts.

3D Systems, meanwhile, rolled out its Figure 4 135 3D printer. Specifically built to address high mix, low volume production needs, the projector-based system is said to provide the adaptability required to meet diverse or fluctuating manufacturing demand.

Alongside its new Figure 4, 3D Systems has also launched a material: Figure 4 Tough 75C FR Black. This ultra-resilient, flame-retardant polymer is ideal for industries like automotive and consumer electronics, which require high durability, heat resistance, and flexibility.

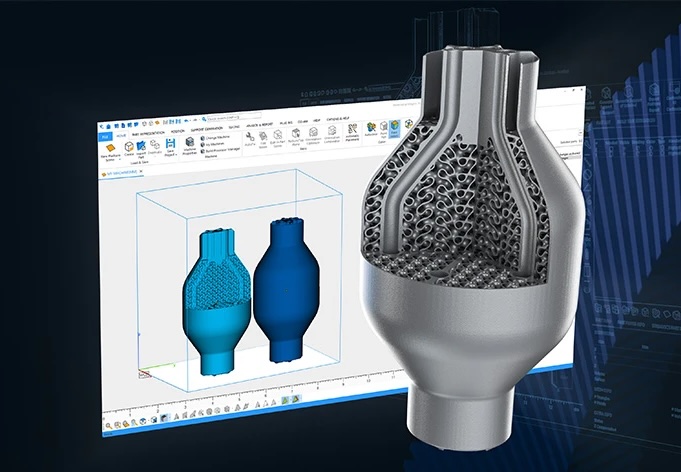

At Materialise, its new Magics software (complete with nTop implicit geometry support) wasn’t the only announcement – it also unveiled partnerships with Raplas and One Click Metal. Together, these deals are expected to help customers overcome design limitation, cost, and lead time issues around 3D printing in areas like aerospace and healthcare.

Lastly, in our heavy-hitter round-up, HP has partnered with Evonik to create a halogen-free flame retardant 3D printing material. The catchily named ‘HP 3D HR PA 12 FR’ offers 60% reusability, lending it greater cost-efficiency while making it better for the environment.

Elegoo & PioCreat shake up desktop 3D printing

In the desktop category, Elegoo announced the launch of its largest resin 3D printer to date: the Jupiter 2. Featuring a 14-inch, 16K display and sizable 302.4 x 161.98 x 300 mm build volume, the machine is designed to allow engineers and hobbyists to scale their 3D printing ambitions.

“The Jupiter 2 is our bold step forward in elevating the resin 3D printing experience,” explained Chris Hong, CEO of Elegoo. “We’re setting a new industry benchmark by delivering a reliable, high-efficiency printer capable of handling demanding projects with consistent results.“

While Jupiter 2 hasn’t quite hit the market just yet, desktop 3D printing fans don’t have long to wait. They can get their hands on it from Q3 ‘25 – although they may need a bigger desktop!

At RAPID +TCT, PioCreat 3D also showcased the HALOT-X1. As reported by 3D Mag, the Creality subsidiary is crowdfunding the latest HALOT 3D printer ahead of an anticipated launch later this year. With a 16K Mono LCD screen, pre-leveled anti-scrape build plate, and built-in resin management system, the HALOT-X1 is one to keep an eye on in the months to come.

On the accessory front, SUNLU showed off its new E2 & SP2 FilaDryers and a whole host of new materials. The company says its latest launches are designed to ensure optimal filament quality and 3D printing consistency, as well as providing access to higher end use cases and results, not just for specialized engineers but everyday creators too.

Innovation outside traditional 3D printing

Elsewhere on the showfloor, there were plenty of other technological innovations on display. US 3D solution provider GoEngineer was demoing Artec Leo, the ultrafast, wireless, AI-powered 3D scanner by Artec 3D. Though the device hit the market a few years ago now, it continues to find new use cases, and provide that ‘wow factor’ – as you can see in the image above!

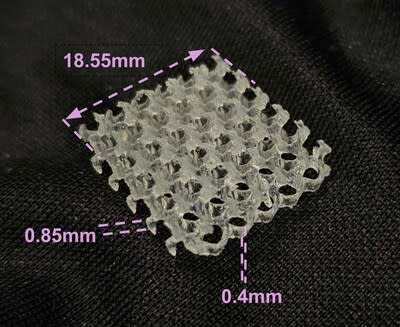

Lastly, Manifest Technologies also took the opportunity to launch the world’s first Parallax Volumetric Additive Manufacturing (P-VAM) evaluation kit. If you’ve never heard of P-VAM, don’t worry you haven’t missed the launch, it hasn’t come out yet.

Using precisely controlled light beams, the technology is said to instantly form multidimensional parts in a way that’s 10-100x faster than traditional layer-by-layer 3D printing. Bold claims from the University of Colorado spin-out! When it does hit the market, it’s expected to pair well with injection molding in volume applications and open entirely new use cases to 3D technology.

“We founded Manifest to fundamentally reimagine additive manufacturing — moving beyond layer-by-layer printing to instant, multidimensional formation of solid parts,” said Manifest Technologies CEO Camila Uzcategui. “At a time when the more mature additive technologies are beginning to stagnate, we view the debut of our P-VAM evaluation kit at RAPID as an invitation to forward-thinking partners to join us and manifest different.“